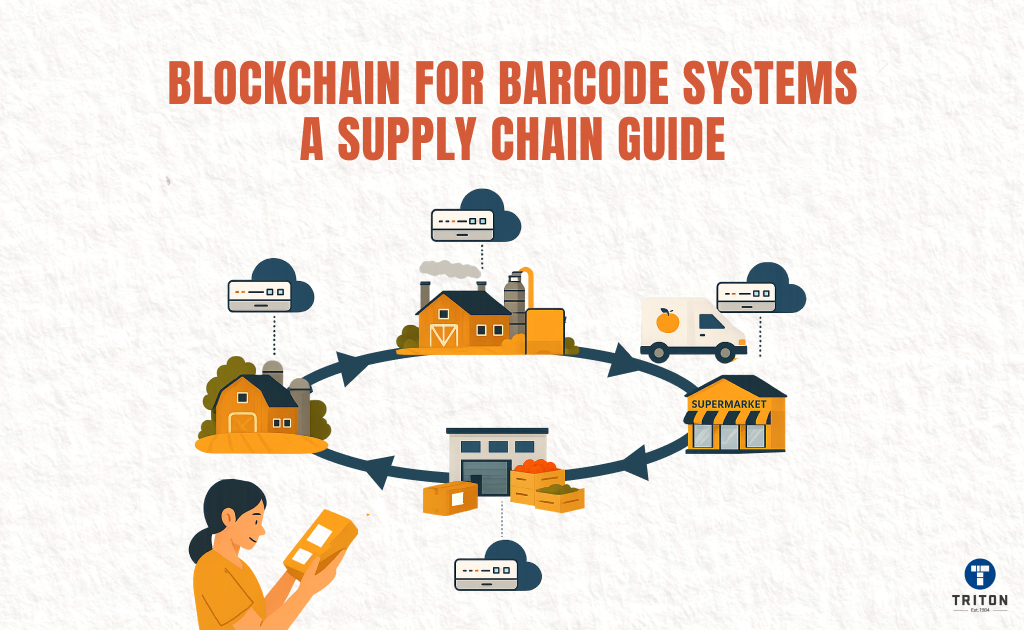

Barcodes are at the heart of modern supply chains, yet only 13% of companies report complete visibility, while 72% say they operate with fragmented data. In sectors like pharmaceuticals, such inefficiencies can shave off 4.5% of annual revenue.

Blockchain technology solves these problems by making safe, unalterable records.

Walmart and IBM’s work on blockchain-based food tracking is an example of how barcodes and blockchain work to improve data accuracy and openness across complex supply chains.

This article examines how combining blockchain technology with barcode systems can improve traceability, increase data security, and streamline processes.

Several problems inherent to traditional barcode traceability systems make supply chains less efficient and resilient.

The lack of access to data in real-time is the biggest issue holding back barcode-only-based supply chains. Relying on batch updates or human data input causes information-sharing delays, which makes it challenging to make decisions quickly and slows down or even stops processes because the data is either old or incomplete.

Data fragmentation further exacerbates these issues. Data stored in multiple formats and systems makes consolidation and analysis a challenge. Errors, unauthorised alterations, and missing information are more likely to occur with manual data input, which results in expensive blunders like erroneous shipment tracking or stock levels.

Issues of interoperability also plague traditional barcode systems. Supply chain partners typically employ different formats and standards, requiring manual data revision, which adds latency and makes mistakes more likely.

For example, a warehouse utilising an outdated barcode system will not sync with a retailer’s cloud-based inventory platform, forcing employees to extract and reformat order data manually.

Security vulnerabilities represent another major issue. A centralised barcode system stores data in a single location and creates a single point of failure.

If this single point is compromised or fails, catastrophic disruptions can occur. For example, a data breach at Oracle Cloud in 2025 reportedly revealed 6 million records from more than 140,000 tenants, which caused supply chain disruptions and ransom demands.

Such incidents highlight the risks of centralised architectures, where a single security breach can halt operations and lead to financial and operational losses.

Integrating blockchain technology with barcode systems introduces several verifiable enhancements in supply chain operations.

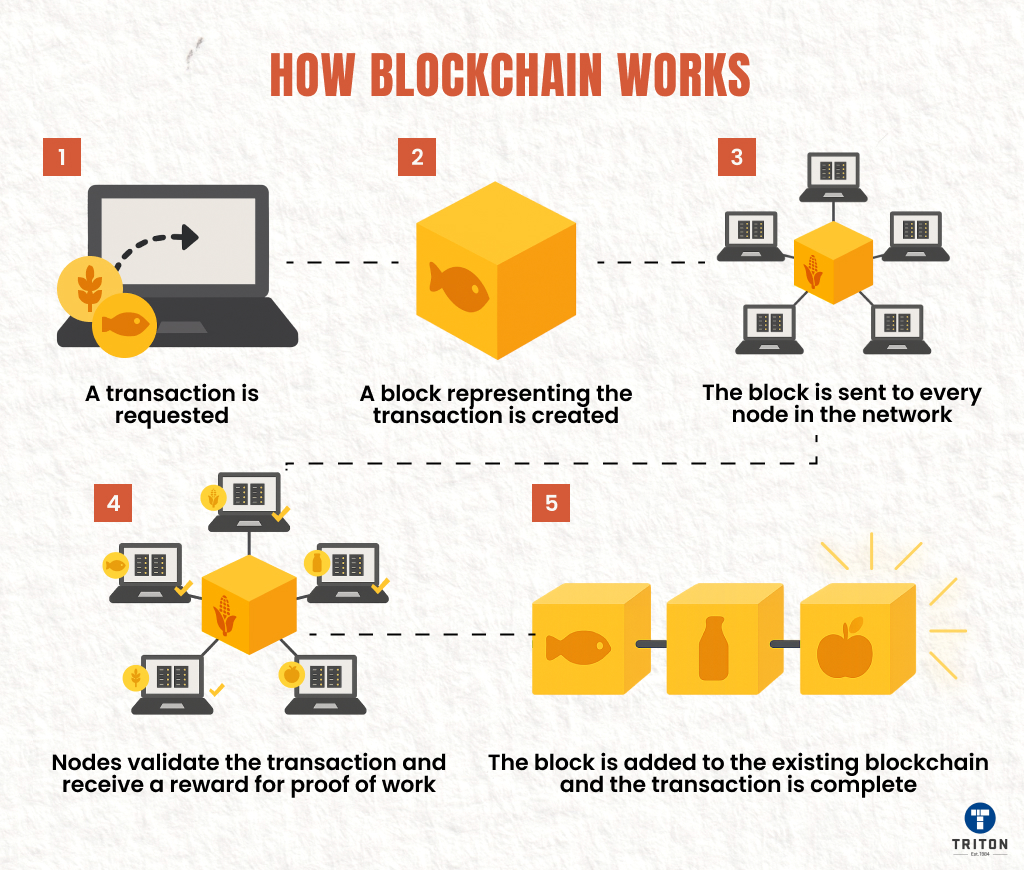

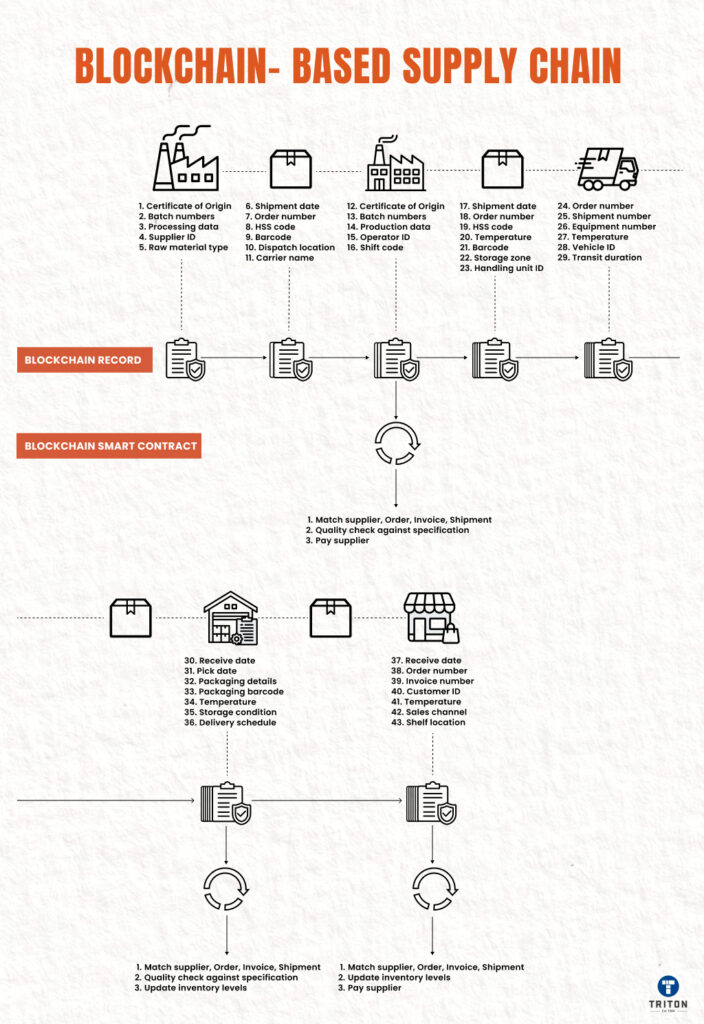

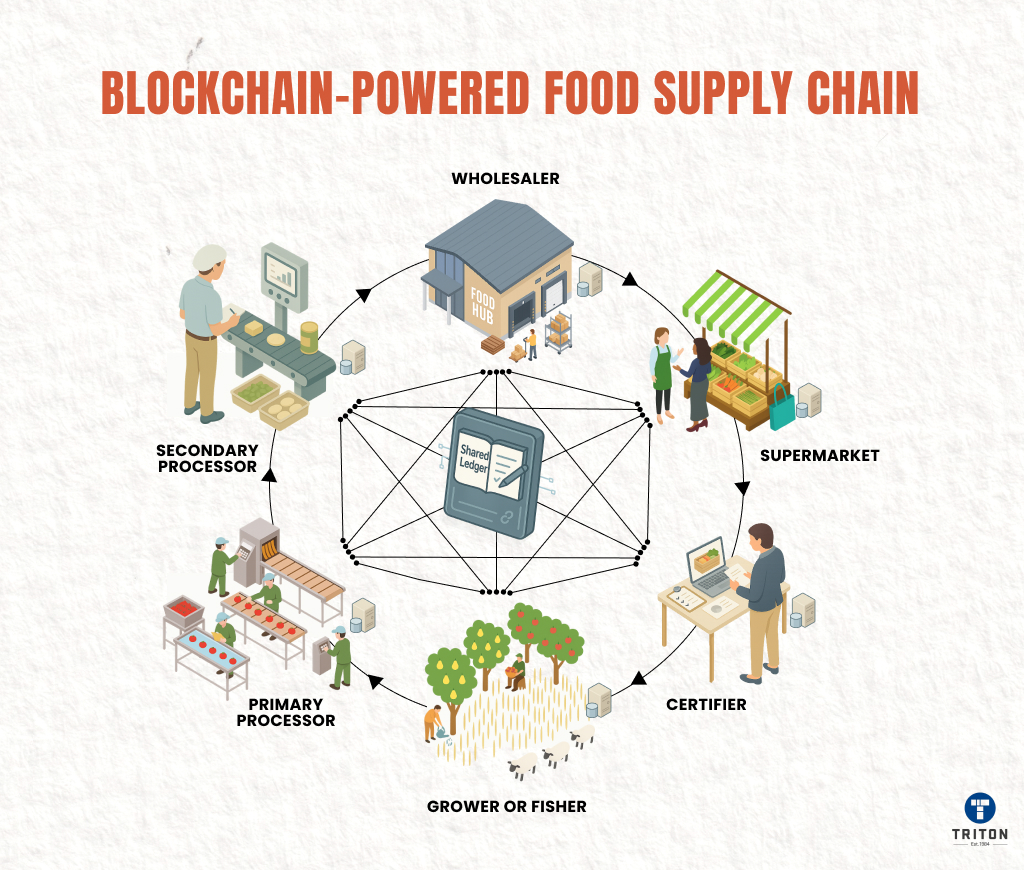

Barcode scan data triggers the blockchain system to create an immutable, timestamped record on a cryptographically secured, shared digital ledger. Each entry logs transaction details like time, location, and status, establishing a verifiable item history accessible only to authorised participants.

Blockchains can also use smart contracts. These are like digital agreements that automatically execute actions when certain conditions are met. They’re stored on the blockchain and can trigger actions like updating inventory or authorising payments when, for example, a delivery is confirmed.

Blockchain automation has demonstrably reduced manual processing steps, minimised associated errors, and accelerated transaction speeds, leading to operational efficiency gains.

While the actual savings may vary depending on the use case and industry, studies have consistently shown lower costs in administration, compliance, and dispute resolution with the integration of blockchain technology.

For regulatory compliance, blockchain creates a secure, unchangeable record of transactions. This makes audits easier by clearly showing where products come from and how they are handled. Industries like food, pharmaceuticals, and high-value goods use blockchain to ensure product safety and prove authenticity.

By adding blockchain to supply chain tracking, you can significantly enhance data security. The decentralisation of information across multiple locations, instead of storing it in one place, reduces the risk of data loss.

Cryptographic hashing protects data from unauthorised changes, making records difficult to alter.

Only approved users can access or add data with permissioned blockchains, ensuring that sensitive information remains safe and secure.

Here is a real-world example to show how these features work in practice.

Walmart uses IBM’s Food Trust platform to trace the source of produce items in about 2.2 seconds. Before blockchain, this process could take days. This faster tracing greatly improves food safety.

Walmart isn’t the only one using blockchain this way. Platforms like OpenSC also use it to give consumers reliable proof that products, such as seafood, come from ethical and sustainable sources. Other uses include tracking the origin of diamonds to ensure they’re not from conflict zones, or verifying the authenticity of high-end fashion items.

Putting blockchain and supply chain barcode systems together takes a step-by-step plan. Proper planning helps you use blockchain’s strengths to get more reliable data, clearer visibility, and make day-to-day work run better. The points below cover the important things to think about for doing this:

Assign each product or batch a unique identifier (e.g., via barcode or QR code) digitally linked to a record on the blockchain.

Utilise barcode scanners, IoT sensors (e.g., temperature, humidity, GPS), and other tracking tools (e.g. UWB tracking system) to automatically capture data points (location, condition, custody changes) at critical stages of the supply chain. Recording this data onto the blockchain creates an immutable, chronological log of the product’s journey.

Select a blockchain platform according to supply chain requirements. Some evaluation criteria are transaction speed, scalability, data privacy capabilities, and consensus mechanisms.

Permissioned blockchains (e.g., Hyperledger Fabric, Corda) allow granular authorisation, which is important for businesses that need to keep some information private. Public or consortium models (e.g. IBM Food Trust, VeChain) are better for wider accessibility or industry collaboration.

Adopt recognised data standards (e.g., GS1 standards like EPCIS for event data) across all participating partners. Standardisation ensures data consistency, simplifies integration between different systems, and enhances interoperability across the supply chain network.

Integrate the blockchain system with enterprise software, such as Enterprise Resource Planning (ERP), Warehouse Management Systems (WMS), and scanning hardware.

Effective Application Programming Interfaces (APIs) enable seamless data flow, minimise operational disruption, and leverage existing technology investments.

Employ smart contracts on the blockchain to automate predefined business logic and workflows where feasible. Use cases include automated compliance verification against set rules, triggering alerts for deviations, or facilitating automatic settlements upon confirmed receipt of goods based on blockchain data.

Initiate a pilot project focusing on a specific product line or part of the supply chain to test the blockchain integration’s functionality, performance, and business impact in a controlled environment. Use findings from the pilot to refine the solution design and integration strategy before considering a broader rollout.

Carry out complete training programs for all involved parties, such as internal teams, suppliers, logistics providers, and customers. Such training helps users grasp their roles and use the new procedures and technology effectively and adequately.

Set up KPIs to track how the combined system works. Examples include data correctness, tracking speed, system availability, operational costs, and user feedback.

Look at these measurements frequently to spot chances for improvement and improve ROI.

Verify that the blockchain implementation adheres to relevant industry-specific regulations (e.g., DSCSA for pharmaceuticals, FSMA for food safety) and data privacy laws (e.g., GDPR). Maintain awareness of evolving standards and regulations in supply chain data management.

A structured implementation prepares the groundwork for successfully combining these technologies. It helps businesses achieve the sought-after benefits: supply chains that better withstand disruptions, offer greater openness, and run more productively.

Blockchain adoption for barcode traceability faces several hurdles.

Implementation demands significant technical expertise and investment, posing challenges, particularly for SMEs.

Scalability limitations and transaction speeds, especially with high-volume scans on public blockchains, can cause delays and raise costs; The industry is exploring hybrid on-chain/off-chain storage models as solutions.

Another major hurdle is the lack of standardised data formats. This absence makes it hard to get the interoperability needed for effective partner collaboration.

Examples of these problems were seen in projects like TradeLens.

Another challenge involves overcoming user adoption resistance, which requires convincing users that the investment makes sense for them and the business, supporting them through necessary changes in work processes, and highlighting the new system’s advantages.

Despite these challenges, blockchain technology is set to enhance barcode traceability by enabling secure, immutable, near-real-time tracking.

Integration with IoT devices allows for the reliable capture and logging of critical environmental or location data onto the blockchain.

This high-integrity data creates a trustworthy foundation for advanced analytics, such as machine learning, for predictive insights into supply chain events.

The ongoing development of global data standards and supportive regulatory frameworks will simplify integration.

As these elements mature, blockchain integration promises improved operational efficiency, reduced fraud, and greater supply chain transparency across the pharmaceutical and food logistics industries.

Integrating blockchain with barcode systems demonstrably enhances traceability across diverse industries, though practical implementations reveal specific challenges alongside the benefits.

Blockchain supercharges barcodes, not replaces them. It tackles traditional data fragmentation and security risks by creating a secure, immutable ledger from scanned data, boosting transparency and trust. While integration hurdles like cost and standardisation remain, ongoing efforts promise wider adoption. Unlock greater supply chain efficiency and security with this powerful combination, ensuring you have the essential hardware and systems in place – visit Triton Store for all your barcode needs.