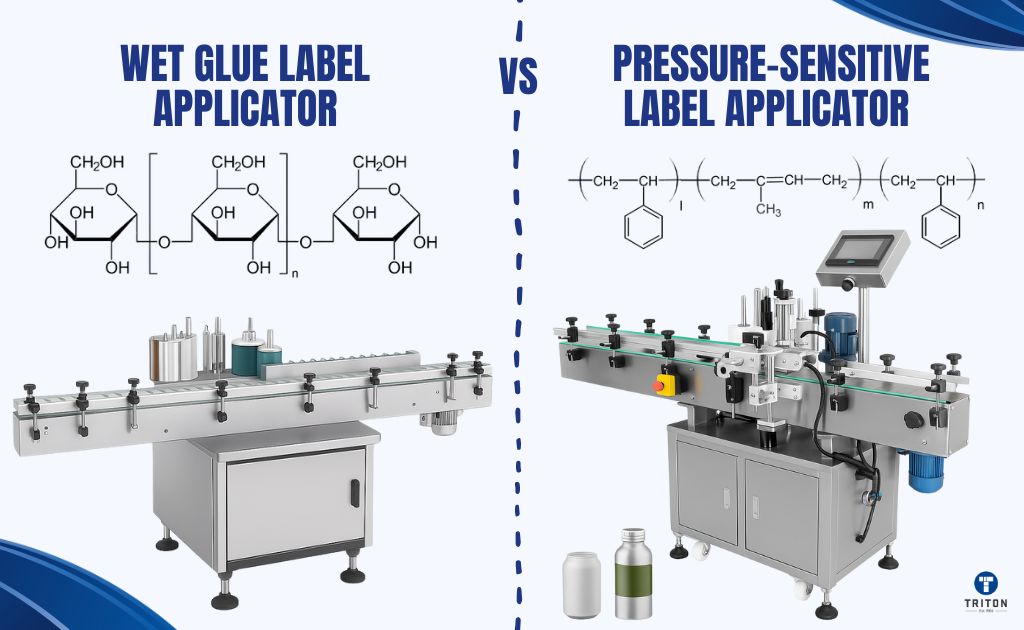

Choosing between pressure-sensitive and wet-glue label applicators impacts production efficiency. Applicator selection influences throughput, material costs, waste management, and changeover frequency, shaping operational economics.

Pressure-sensitive systems dominate; forecasts show they will claim over 72% market share by 2025.

Pressure-sensitive label applicators can apply labels with existing adhesive coatings at speed onto many surfaces.

Wet-glue systems apply liquid adhesive during the process. They create bonds with high integrity, particularly on glass and metal, representing a market growing towards USD 14 billion.

Which technology offers superior performance? This article compares applicator speed, bond characteristics, material handling, waste, and costs.

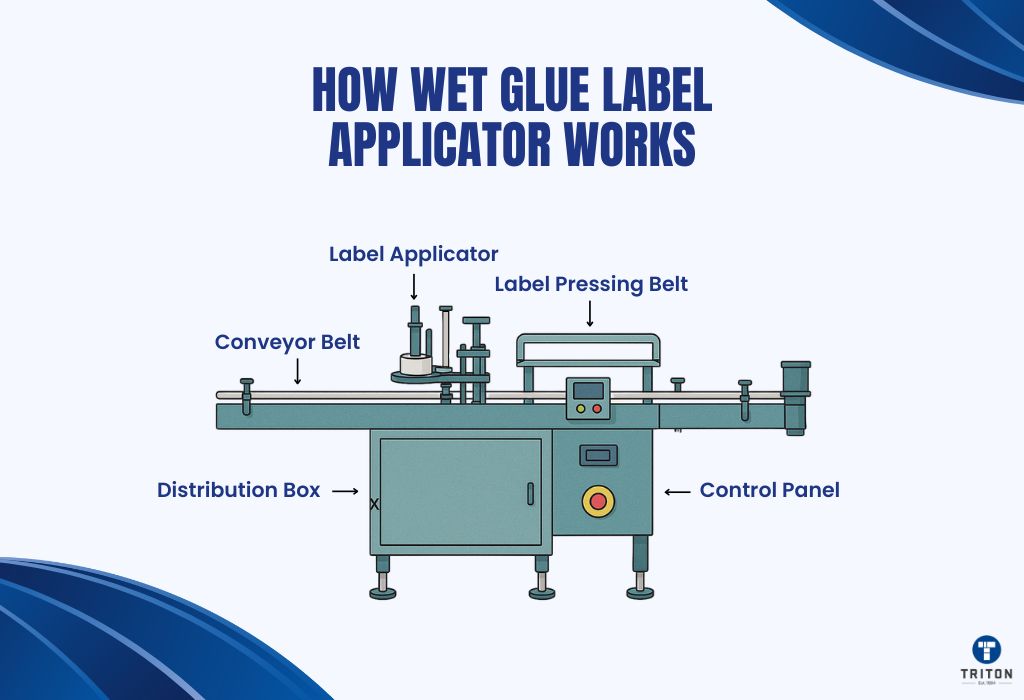

Wet glue label applicators, also called cut-and-stack and glue-applied labellers, affix labels using liquid adhesive dispensed during production. In contrast, pressure-sensitive label applicators work with pressure-sensitive labels with pre-applied adhesive.

In wet glue systems, an application head, often using a roller or nozzle design, coats either the label back or a transfer surface (like a pallet) with adhesive. A vacuum or mechanical system then picks the individual label from a magazine stack, places it onto the container, and presses it onto the container surface.

Common adhesive types include cold glue (water-based polymer emulsions) and hot melt glue (thermoplastics).

Wet-glue label applicators span speeds from entry-level semi-automatic units at 40-60 bottles per minute (bpm) up to ultra-high-volume rotary systems exceeding 1,000 bpm. Most single-head, fully-automated machines in food and beverage lines operate between 100 and 350 bpm, with bench-top and semi-automatic models at 40-60 bpm. Integrated multi-head setups or gravure-printed wet-glue lines can reach 60,000-80,000 containers per hour (1,000-1,333 bpm) under ideal conditions.

Industries select wet glue label applicators for high-speed labelling operations and achieving economy during long production runs. Common applications include:

The two primary adhesive classes in wet glue labelling are water-based cold emulsions and solvent-free hot melt adhesives.

Modern cold glues are typically polymer emulsions, not simple starch mixes. They are predominantly based on synthetic polymers like Polyvinyl Acetate (PVA) or acrylics, stabilised as dispersions in water, usually formulated with 40-60% solid content.

Starch or dextrin-based adhesives are still used for basic paper/board applications and where cost matters.

Synthetic emulsions provide more consistent bond strength, application performance, and shelf life for demanding labelling operations.

Special cold glue formulations include additives such as tackifiers, crosslinkers (to improve water resistance), and anti-fungal agents.

Cold glues are applied at room temperature and set as water evaporates from the glue line or is absorbed by porous substrates, which forms a cohesive polymer bond with the container.

The drying time ranges from minutes under ambient conditions to seconds when accelerated with forced air, infrared (IR) heaters, or other drying systems.

Food-grade wet glues comply with food contact regulations (e.g., FDA 21 CFR 175.105, EU 10/2011).

Food-grade wet glues have low Volatile Organic Compounds (VOCs) and no added formaldehyde.

Key Characteristics:

Hot melt adhesives are 100% solids, solvent-free thermoplastic formulations with two main components: the base polymer and additive.

The base polymers commonly include Ethylene-Vinyl Acetate (EVA), polyamides, or polyolefins (including metallocene-catalysed variants).

These are blended with additives like tackifiers (to modify surface stickiness), plasticisers, waxes (to control viscosity and set speed), and antioxidants (for thermal stability).

They are applied in a molten state, heated to temperatures typically ranging from 120°C to 200°C (approx. 250°F-390°F) using heated tanks, hoses, and applicator nozzles.

Bonding occurs via a physical phase change. The adhesive solidifies almost instantly (often under one second) as it cools below its softening point, creating a rapid bond.

Ethylene-vinyl acetate copolymers (20-40 % VA), polyolefins (amorphous poly-α-olefin and metallocene-catalysed PE/PP), styrene block copolymers (SBS/SEBS), polyamides (nylon-type polymers), reactive polyurethanes (PUR) and polyester-based systems are examples of some food-contact approved hot-melt adhesives.

Key Characteristics:

Feature | Cold Glue (Water-Based Emulsion) | Hot Melt Adhesive |

|---|---|---|

Solids Content | 40-60% | 100% |

Primary Polymers | PVAc or acrylic emulsions | EVA, polyolefin and polyamide |

Application Temperature | Ambient (20-25 °C) | Molten (120-200 °C) |

Setting Mechanism | Water evaporation & film formation | Cooling & solidification

|

Typical Set Time | Seconds (with IR/air drying) to minutes | < 1 second |

Approximate Open Time | 5-15 minutes (up to 30) | < 2 seconds |

Typical Viscosity (cP) | 7,000-15,000 @ 23 °C | 900-3,000 @ 150-180 °C

|

Primary Substrates | Porous (paper, cardboard) | Non-porous (plastics, metal, glass), coated paper |

Energy Consumption | Low (pumps + drying) | High (continuous heating)

|

Regulatory Options | Food-contact, low-VOC, biodegradable | Food-contact (FDA & EU), low-migration |

Service Temperature Range | -40 to +80 °C | -40 to +80 °C |

Wet glue performance depends on label material and substrate properties like surface energy, porosity, and strength.

Common Label Materials:

Label Material | Surface Energy | Treatment Required | Recommended Adhesive |

|---|---|---|---|

Coated Paper | ~100 dyn/cm | None | |

Uncoated Paper | ~38 dyn/cm | None | PVA emulsion |

Kraft Paper | ~38 dyn/cm | None | High-tack PVA blend |

Metalized Paper | ~45 dyn/cm | None | High-tack acrylic emulsion |

Synthetic Paper | 29-42 dyn/cm | Corona/plasma to ≥45 dyn/cm | Modified acrylic emulsion |

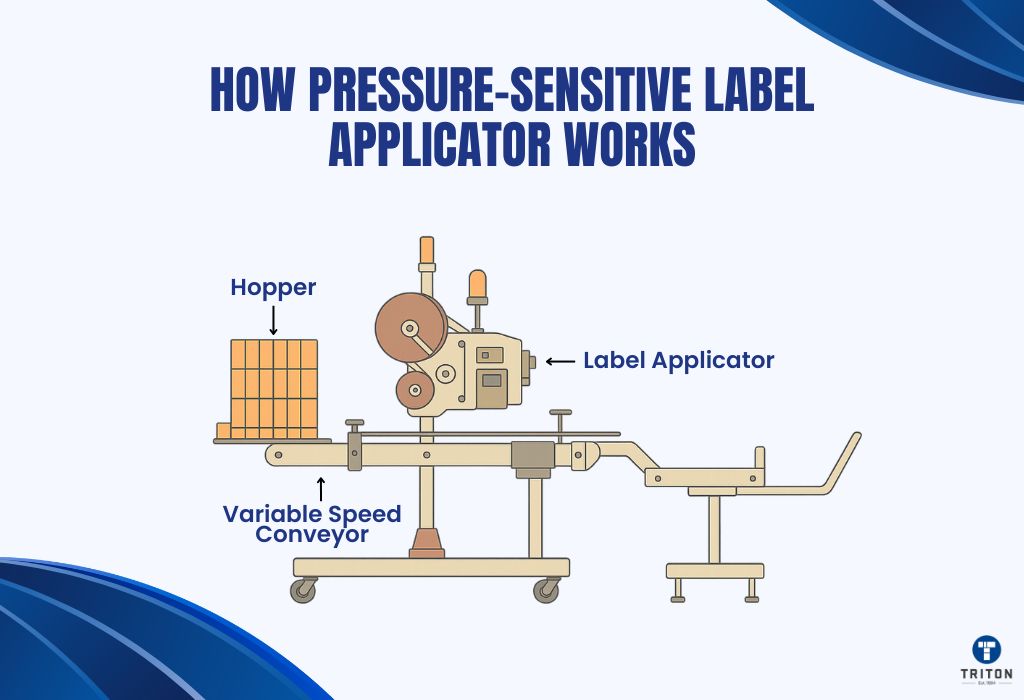

These machines feed pre-coated labels on a roll, peel off the liner, and apply labels by pressure without extra glue.

They support permanent, removable and repositionable adhesives, run automatically at speeds up to 1,000 labels/min, and use sensors and vision systems for placement and quality checks.

Applications span plastic bottles, flexible pouches, cartons and industrial drums. Materials include paper, film, foil and durable synthetics.

Pressure-sensitive label applicators operate at around 5 CPM for manual hand-wipe units, up to 40 CPM for bench-top semi-automatic printers, and 20-250 CPM for portable industrial applicators.

Inline wipe-on, tamp-blow, and merge heads run between 50-250 cpm; specific historical models showed different ranges, with early FS1 units running 25-300 cpm and FS2 prototypes achieving 200-500 cpm.

Air-blow systems achieve peak speeds of 1,000 cpm. High web-speed merge applicators can process 5,000 inches of label web per minute (1,200-1,500 cpm.)

Print-and-apply units deliver 40-175 cpm, combining coding and labelling functions in one pass.

Pressure-sensitive applicators are versatile and are used by almost all industries, from craft operations to high-throughput production lines, which need tailored adhesion and accuracy. Common applications include:

Pressure-sensitive adhesives remain permanently tacky at room temperature and form a bond under light application pressure. Key adhesive chemistries include acrylic, rubber, silicone, and urethane systems.

Acrylic Adhesives: Acrylic pressure-sensitive adhesives utilise copolymers of acrylic acid esters.

Formulations typically contain 50-70% polymer solids in water or solvent emulsions, combined with tackifier resins (10-30%) and plasticisers (2-6%). These adhesives demonstrate high resistance to UV light, oxidation, and ageing. They provide stable tack and high shear resistance (>10 hr) over service temperatures from -20°C to +80°C, with peel strengths typically 1-5 N/25mm.

Rubber-Based Adhesives: Rubber-based systems employ natural rubber (polyisoprene) or synthetic elastomers like styrene block copolymers (SIS, SBR). Solvent-based formulations usually contain 40-60% polymer solids with 20-40% tackifier content. Rubber adhesives deliver high initial tack, making them economical for certain applications. However, they exhibit low UV light and heat resistance, limiting service temperatures (around -5°C to +60°C) and ageing characteristics. The shear resistance is low (<1 hr), with peel strengths often 0.5-2 N/25mm.

Silicone Adhesives: Silicone adhesives use polydimethylsiloxane polymers, often crosslinked and delivered in solvent carriers (20-50% solids) with reinforcing fillers. They maintain performance over a wide temperature range (-60°C to +250°C) and bond to low-energy surfaces. Silicone systems resist moisture and chemicals. Their cohesion is lower than acrylics, and costs are higher. Initial tack is low, peel strength is 1-3 N/25mm, and shear resistance averages around 5 hours.

Urethane Adhesives: Urethane adhesives are moisture-curing or thermoplastic polyurethane dispersions (40-65% solids). After application, they form crosslinked networks, yielding strong cohesion and chemical resistance across service temperatures from -40°C to +120°C. These properties suit demanding industrial labelling.

Other Formulations: UV-curable acrylic systems offer solventless application, curing rapidly under UV light for high shear performance. Hybrid formulations blend different polymer chemistries to achieve precisely defined properties.

Adhesive performance results from balancing base polymer (40-70% for cohesion), tackifiers (10-40% for initial stick), plasticisers (2-10% for flexibility), and other stabilisers or fillers.

Pressure-sensitive labels can be paper, film, foil, or speciality synthetic facestocks.

Paper facestocks include coated papers (80-120 gsm) for sharp printing, uncoated papers (70-100 gsm), and thermal papers for direct printing. The paper offers good printability and lower cost and is suitable for indoor applications.

Film stocks provide durability and a barrier against moisture, chemicals, or abrasion. Biaxially Oriented Polypropylene (BOPP) (30-50 µm) resists moisture and oils and is common in food labelling. Biaxially Oriented PET (BOPET) (12-36 µm) has high strength, stability, and resistance to UV, heat, and solvents. Polyethylene (PE) has flexibility for low temperatures (< -40°C) and is used in squeezable packaging.

Foil laminates (>6 µm) and metallised PET films (12-25 µm) have premium metallic appearances and good barrier properties and are used in high-end goods and tamper-evident labels.

Specialty synthetics are used in demanding applications. Vinyl (PVC) (75-125 µm) conforms well to irregular shapes for outdoor or long-life applications. Synthetic papers (130-230 gsm) can be printed like paper and are tear and moisture-resistant.

Surface treatments (corona, plasma) increase film surface energy (>45 mN/m), improving ink and adhesive wetting. Topcoats add protection and modify finish.

Feature | Acrylic-Based PSA | Rubber-Based PSA | Silicone-Based PSA | Urethane-Based PSA |

|---|---|---|---|---|

Solids Content | 50-60% | 40-54% | 20-50% | 40-65% |

Primary Polymers | Copolymers of acrylic esters | Natural rubber or styrenic block copolymers | Polydimethylsiloxane networks | Thermoplastic or moisture-cure polyurethanes |

Application Temperature | Ambient (20-25 °C) | Ambient (20-25 °C) | Ambient (20-25 °C) | Ambient (20-25 °C) |

Setting Mechanism | Instant tack under pressure | Instant tack under pressure | Instant tack under pressure | Instant tack; moisture cure over time |

Service Temperature Range | -20 °C to +80 °C | -5 °C to +60 °C | -60 °C to +250 °C | -40 °C to +120 °C |

Regulatory Options | FDA & EU food-contact, low-VOC

| FDA & EU food-contact | FDA & EU indirect food-contact

| FDA & EU food-contact

|

Key Additives | Tackifiers, plasticisers, crosslinkers | Tackifiers, plasticisers, antioxidants | Fillers, minimal tackifiers, catalysts | Isocyanate, catalysts, plasticisers

|

Selecting the appropriate labelling technology—wet-glue or pressure-sensitive—is an operational decision with direct consequences for throughput, cost, and brand presentation.

The optimal choice emerges from a rigorous analysis of six core operational parameters against the capabilities of each system. This framework clarifies the trade-offs and leads to a data-driven selection:

Match applicator throughput to your line’s average and peak speeds.

Consider the container material, shape, and surface characteristics.

Analyse the frequency of label or product changes and the associated setup time.

Evaluate requirements for bond strength, repositionability, and environmental resistance.

Assess waste generation, energy consumption, and compliance needs.

Compare initial investment with ongoing operational expenses.

Category | Wet Glue Labellers | Pressure-Sensitive Labellers |

|---|---|---|

Initial Equipment Investment * | Semi-automatic: US $800-1700

Fully automatic: US $6000-1 000

| Hand-held: US $129-142

Semi-automatic bench-top: US $1900-4740

Fully automatic: US $30000+

|

Operational Costs * | Adhesive: US $0.65-2.00 per kg emulsion | Labels: US $0.04 each (bulk drops to US $0.05) |

Label Material Cost * | Paper labels: US $0.005-0.01 each (bulk) | PS paper/film labels: US $0.02-0.04 each (bulk) |

Cost-Effectiveness by Scale | More economical above 10000 labels per run | Better for runs below 10000 labels |

Production Line Speed (cpm) | Table-top/semi-auto: 60-100

Single-head auto: 100-350

Rotary/gravure: up to 1 000 | Hand-held: 15-20

Inline wipe-on/tamp-blow: ~20-250

High-speed air-blow: up to 1 000 |

Changeover Time | 10-15 minutes | 2-5 minutes per roll swap |

Downtime & Maintenance | Glue-head cleaning every 4 h (~15 min) | Sensor/roller checks monthly (~30 min) |

Placement Precision | ±1.0 mm | ±0.25-0.5 mm |

Defects & Common Issues | Wrinkles/smears in 0.5-1 % of labels | Peeling/static misfeeds in 0.2-0.5 % |

Aesthetic Quality | Classic paper-based look | High-resolution print; matte, gloss, metallic |

Container Compatibility | Glass, metal; limited on plastics | Glass, plastic, metal, flexible films |

Suitability for Shapes & Sizes | Cylinders ≥30 mm dia.; less on odd shapes | Flat, curved, irregular; label height ≥10 mm |

Specialty Labels | Standard paper/film | RFID, tamper-evident, smart labels |

Environmental Conditions Impact | Holds at 0-60 °C; weakens above 80 % RH | Standard PSAs -20 °C to +60 °C; specialties to +80 °C |

Adhesion Strength (Peel N/25 mm) | 4-6 N (paper/glass)

| 2-4 N permanent; 0.5-1 N removable |

Setup & Training | 8-16 h for glue prep and tuning | 2-4 h for roll threading and sensors |

Waste & Recyclability | ~2 % adhesive residue; labels biodegradable | Liner ≈35 % of laminate; half of label mass |

Energy Consumption | Drying ovens 1-2 kW; pumps 0.1 kW | Pneumatics & controls 0.2-0.5 kW |

* The costs are indicative

The right label applicator optimises labelling operation. Wet-glue is cost beneficial for high-volume, consistent runs on rigid containers. Pressure-sensitive is flexible for diverse products, materials, and frequent changeovers.

Prioritise these factors based on your operation’s unique demands. Validate your choice through vendor consultation and trials. For tailored labelling supplies, visit the Triton Store.