Thermal transfer ribbons are a key variable in any label printing system. Their formulation affects print quality, material compatibility, and label longevity – especially in high-throughput environments. Yet many operations treat ribbons as an afterthought.

That’s a mistake.

Ribbon selection impacts printhead life, compliance, and scan accuracy at scale.

Consider this: wax-resin ribbons typically have a total thickness of around 7.6 micrometres, with a base film thickness of 4.5 micrometres and an ink melting point of approximately 87°C. These specifications not only influence the print quality but also the durability of the printed image, affecting its resistance to smudging and scratching.

This guide cuts through the generic advice and focuses on what professionals need to know: how thermal ribbons function, how wax, wax resin, and resin types perform under pressure, and how to select the right ribbon for your materials, environment, and printer if your labels carry risk or cost, the ribbon matters.

Thermal transfer ribbons are used in thermal transfer printing to move ink onto a label using heat. This technology gained popularity in the 1980s as businesses required more durable labels than what dot matrix and inkjet printers could provide.

Unlike direct thermal printing, which burns the image into heat-sensitive paper, thermal transfer printing uses a ribbon as the ink source.

The print head heats the ribbon which melts the ink on the ribbon. The ink sticks to the label surface to create the print. This method produces longer-lasting, more resistant prints – essential in logistics, warehousing, and industrial labelling.

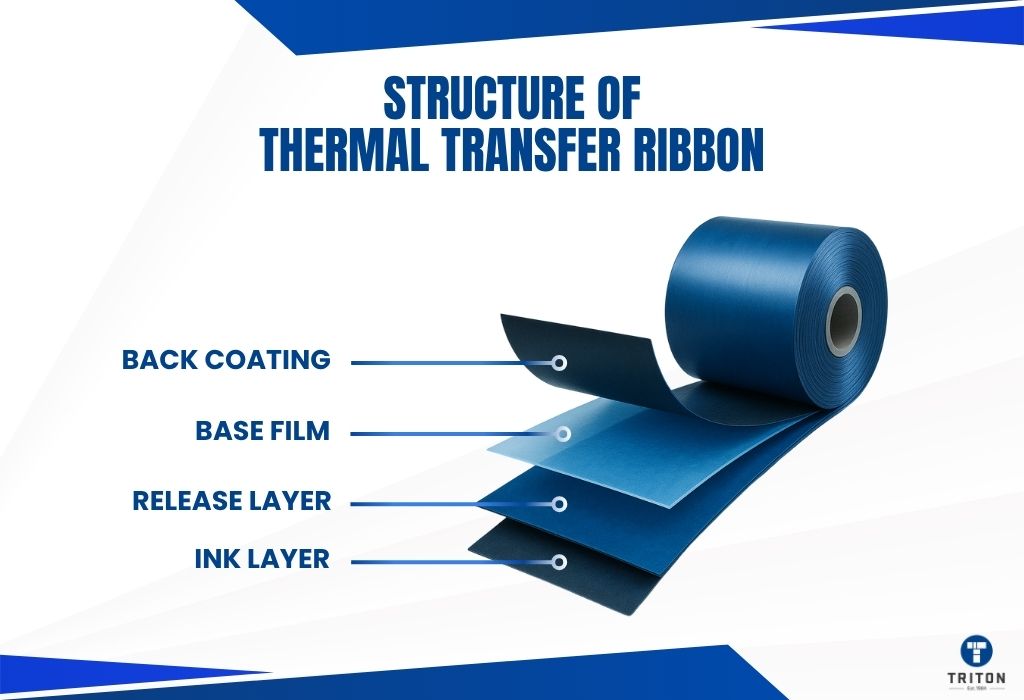

A standard thermal transfer ribbon has four layers. Each one plays a role in the printing process and affects how well the ribbon performs.

Not all thermal transfer ribbons have the same structure.

Basic wax ribbons consist of only three layers: a back coating, base film, and ink. These are used for general-purpose paper labelling and short-term indoor use.

On the other end, some resin ribbons have five or even six layers. These include an extra primer to help the ink stick better to the base film and a topcoat to protect the printed image from abrasion or harsh chemicals. These ribbons are used for more durable prints in applications like chemical drum labelling, electronics, and outdoor asset tracking.

Some ribbons go further. In printed electronics, conductive thermal transfer ribbons have up to seven layers, including a conductive ink layer composed of silver or carbon. These ribbons print functional circuits, such as RFID antennas.

Thermal transfer ribbons come in three basic types: wax, wax resin, and resin. Each type contains inks made from materials like paraffin wax, polyethylene wax, or tough resins such as phenolic and acrylic.

Manufacturers select these ingredients based on the label materials they’re printing – whether standard paper or tougher synthetic materials such as polypropylene, polyester, or vinyl.

Additives such as carbon black and titanium dioxide enhance image clarity, while slip agents facilitate smoother printing. These components determine how the printed labels withstand sunlight, chemicals, heat, and rough handling.

Let’s look at these types.

Wax thermal transfer ribbons typically consist of four layers: a polyester (PET) film base, a back coating for print head protection, a release layer, and a wax-based ink layer.

The base film is typically around 4.5 microns thick, providing dimensional stability and facilitating uniform heat conduction during the printing process.

The wax ink primarily consists of paraffin wax, polyethylene wax, and pigments such as carbon black, with additives like titanium dioxide for opacity and slip agents to improve print head glide. Wax ribbons also come in colours such as red, blue, green, yellow, and white. Coloured wax ribbons use similar formulations with pigments like Diarylide Yellow (Pigment Yellow 12), for yellow hues, Phthalocyanine Blue (Pigment Blue 15:3) for blue coloration and Quinacridone Red (Pigment Red 122) for red hues.

Manufacturers use blends of different waxes to tune the ink’s melting point, viscosity, and adhesion characteristics.

High-quality ribbons have ink melting points around 65°C, which means efficient transfer at lower heat. The ink layer itself typically ranges in thickness from 2.0 to 3.2 microns.

Back coatings utilise silicone or antistatic formulations to reduce friction and prevent static build-up, thereby extending print head life.

Standard wax ribbon properties include optical densities greater than 1.8 MacBeth Densitometer units, ensuring clear barcodes and readable text. Abrasion and chemical resistance, while limited compared to resin formulations, are suitable for applications with minimal physical stress or chemical exposure.

Image smudging resistance averages around 50 cycles with a 100-gram load, as measured by standard industry rub tests. Recommended storage conditions to maintain ribbon integrity are between 5°C and 35°C, with humidity levels below 80%.

Manufacturing involves precisely blending waxes, resins, pigments, and additives, followed by slot-die or gravure coating processes onto PET film. After coating, the ribbons undergo controlled drying and curing to achieve their final properties, after which they are slit to the required widths.

Resin thermal transfer ribbons typically consist of four layers: a polyester (PET) film base, a back coating that protects the print head, a release layer, and a resin-based ink layer.

The base film is approximately 4.5 microns thick, providing mechanical strength and consistent heat transfer. The release layer is formulated to handle higher transfer temperatures needed for resin ink. Back coatings use silicone or antistatic compounds to prevent static build-up and reduce friction with the print head.

The ink layer consists of durable synthetic resins. Typical resins include polyester, acrylic, polyurethane, epoxy, and polyvinyl chloride (PVC). These are blended for high abrasion, heat, solvent, and chemical resistance. Resin inks also use carbon black for black prints and titanium dioxide, phthalocyanine blue, and lithopone for coloured variants. Resin colour options include black, red, blue, green, white, gold, silver, and matte metallics.

To enhance performance, manufacturers add dispersants, defoamers, cross-linkers, and polyethylene or talc fillers – these control viscosity, pigment stability, layer smoothness, and film strength. Cross-linking agents are used to harden the resin layer under heat and improve chemical resistance.

Resin inks typically melt at 105 – 112°C. The ink layer thickness ranges from 2.7 to 4.9 microns. Total ribbon thickness is usually below 9 microns for printer compatibility. Optical density often exceeds 1.7 on MacBeth Densitometers, enabling sharp and durable prints. Image smudging resistance averages around 100 cycles with a 100-gram load at 100°C.

These ribbons are manufactured using gravure or slot-die coating onto PET film, followed by drying, curing, and precision slitting. Storage conditions should be maintained between 5°C and 35°C, with humidity below 80%, to prevent degradation.

Resin Type | Key Properties in Thermal Transfer Ribbon Applications |

|---|---|

Polyester | High mechanical strength and flexibility.

Excellent chemical resistance.

Thermal stability suitable for high-temperature printing.

Good adhesion to synthetic substrates like PET and PVC. |

Acrylic | Superior weatherability and UV resistance.

Strong adhesion to various substrates.

Maintains print quality under outdoor conditions.

Suitable for labels exposed to sunlight and varying climates. |

Polyurethane

| High abrasion and scratch resistance.

Flexibility for curved or uneven surfaces.

Good chemical resistance.

Ideal for applications requiring durability and flexibility. |

Epoxy | Exceptional chemical resistance, including solvents.

Strong adhesion to a wide range of substrates.

High durability under harsh environmental conditions.

Suitable for industrial labels exposed to chemicals and heat. |

Polyvinyl Chloride (PVC) | Good durability and weather resistance.

Fire retardant properties.

Effective adhesion to plastic substrates.

Commonly used for labels on PVC cards and containers. |

Wax-resin thermal transfer ribbons comprise a polyester base film, a back coating, a release layer, and a blended ink layer consisting of waxes and resins. The ink layer typically includes paraffin or polyethylene wax for smooth melting and transfer, combined with thermoplastic resins such as acrylic or polyurethane for added durability.

The melting point of the ink layer ranges between 70°C and 90°C, which requires moderate energy from the printhead. The layer thickness typically ranges from 2.5 to 4.0 microns. Additives include carbon black for opacity, titanium dioxide for brightness, and slip agents to manage friction.

These ribbons form semi-durable prints with improved scratch, smudge, and mild chemical resistance over full wax formulations. The blended ink adheres to coated papers and some synthetic surfaces like polypropylene and polyethylene. Optical density often exceeds 1.8 on MacBeth Densitometers, and image durability averages around 75 rub cycles with a 100-gram load under standard testing conditions.

Feature | Wax Ribbon | Wax-Resin Ribbon | Resin Ribbon |

|---|---|---|---|

Primary Binder Composition | Predominantly Wax | Blend of Wax & Resin | Predominantly Resin |

Key Chemical Examples | Carnauba Wax, Paraffin Wax | Ethylene-vinyl acetate copolymer, Polyamide resins + Waxes | Polyester Resins, Acrylic Resins, Polyurethane Resins |

Typical Melting Temp. / Print Energy | Low (e.g., 60-90°C suggested for some wax-heavy inks) | Medium (e.g., 70-120°C suggested) | High (e.g., 110°C, or 120-170°C suggested) |

Print Speed Capability | High | Medium to High | Low to Medium (though some specialized resins can be high-speed) |

Abrasion Resistance | Low | Moderate | High to Excellent |

Chemical Resistance | Low | Moderate to Good | Excellent |

Heat Resistance (Post-Print) | Low | Moderate | High to Excellent |

Typical Substrates | Uncoated & Coated Paper | Coated Paper, Matte & some Glossy Synthetics (PP, PET, PVC) | Synthetic Films (Polyester, Polypropylene, Vinyl, Polyimide, Nylon) |

Relative Cost | Relative Cost | Medium | High |

Common Applications | Shipping labels, retail tags, general purpose indoor, inventory labels | Product labeling, shelf tags, asset tracking, logistics, some synthetics, moderate durability needs | Harsh environments, chemical exposure, outdoor use, automotive, electronics, medical, textile/garment care |

Smudge Resistance | Low | Moderate | High to Excellent |

Choice of thermal ribbon is more than a supply item; it’s a direct lever on label’s performance and system’s efficiency. Understanding the chemistries and constructions of wax, wax resin, and resin, let’s you unlock the ability to match the ribbon to the task. This informed selection ensures your labels not only adhere but also endure, communicate clearly, and support your operational goals without fail. For durable, performance-driven solutions matched to your label materials and printing environment, explore the options available at the Triton Store.