Fanfold labels are thermal labels configured in a continuous, accordion-style sheet. Unlike traditional roll labels wound on a core, their “fanfold” design allows them to stack flat, much like computer paper was once folded.

The distinctive “fanfold” design gets its name from the way the labels stack flat in a concertina-style arrangement, eliminating the need for a central core like traditional roll labels.

Fanfold labels are commonly pressure-sensitive. However, some fanfold labels may have different adhesive properties or be used as tags without adhesive.

These labels come on a perforated “backing” sheet. They’re dispensed from boxes, allowing users to pull, tear, and apply them as needed. While older versions had sprocket holes for pin-feed printers, modern fanfold labels are coreless and do not have these holes and are almost always used with direct thermal and thermal transfer label printers.

Fanfold labels are produced in a continuous strip. This strip is then perforated and folded at regular intervals – often every 4 or 6 inches – creating an accordion stack. This label format can hold more labels per box compared to traditional roll thermal labels.

For example, a typical fanfold stack may contain 1,000–2,000 labels per box, while a standard roll format typically holds 250–1,000 labels on a 1-inch or 3-inch cardboard core. Because fanfold labels don’t have a core, they are more space- and cost-efficient, as there is no wasted space or core material to discard.

The perforations between individual labels – commonly spaced every 4″ × 6″, 4″ × 4″, or 2″ × 1″ – allow for easy separation and consistent feeding through both thermal printers and industrial printers. Fanfold adhesive labels are typically packed in compact boxes. For example, a box of 1,000 fanfold shipping labels may use only about 25% of the storage space compared to the same quantity of roll labels, which can be bulky and require dedicated holders.

For high-volume printing, fanfold labels require fewer reloads. Thousands of labels can be printed before needing to reload, which reduces downtime and labour. Their flat stacking also means less curling, so each label is ready for immediate use, supporting easy handling and more efficient workflows.

Fanfold labels are ideal for large batch size printing when space is at a premium and high printing speeds are required. The accordion pattern holds more labels per stack, has no core waste, and is available in a range of materials and label sizes.

Fanfold labels provide businesses with a practical and cost-saving solution for meeting labelling requirements and making informed decisions about their labelling operations.

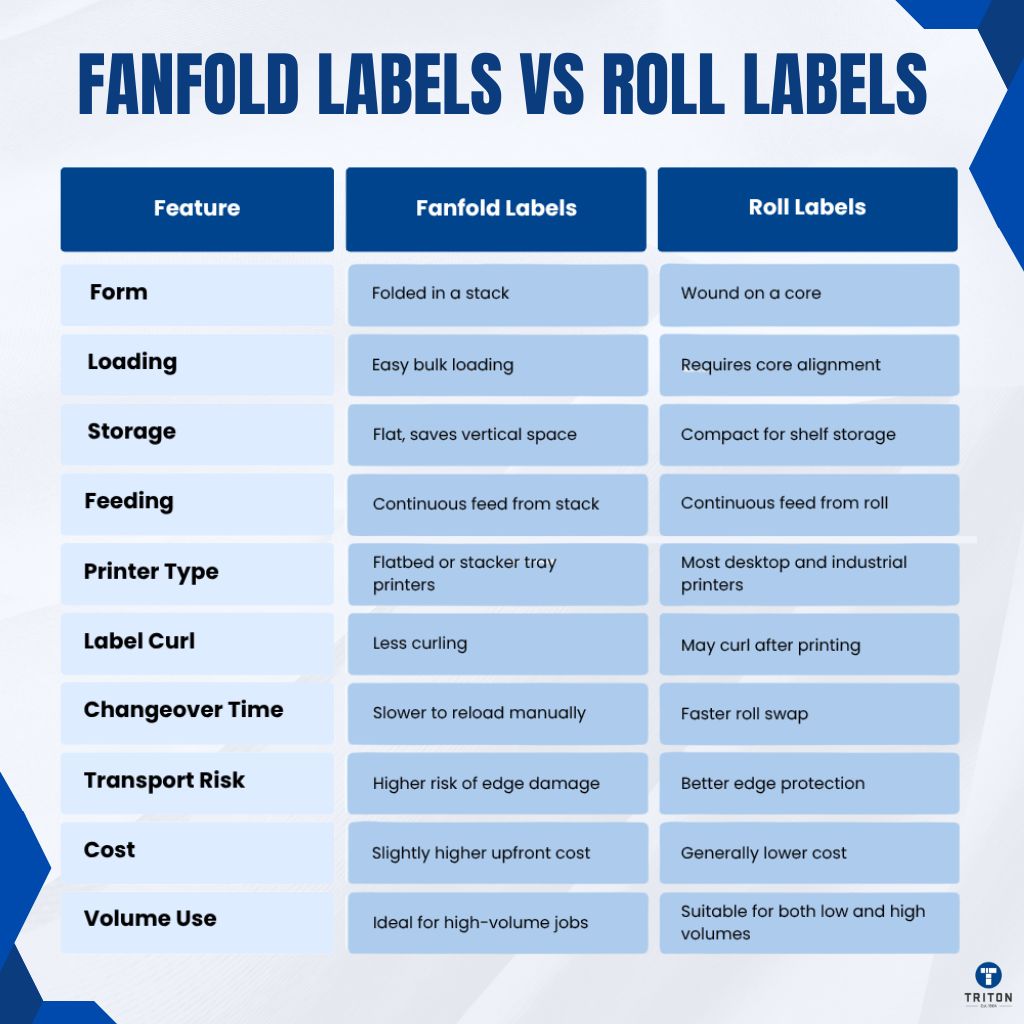

Feature | Fanfold Labels | Label Rolls (Standard) |

|---|---|---|

Labels Print | High-volume, continuous batch printing | Continuous or on-demand printing |

Printing Process | Feeds from stack, flat output, easy handling | Feeds from roll, labels may curl after printing |

Label Rolls | No roll, accordion-folded stack | Labels wound on a cardboard core |

More Storage Space | More labels stored per box, compact stacking | Bulkier rolls require more storage room |

Perfect Label | Flat, ready-to-use labels; less curling | Labels can curl, may need to be flattened |

Cost Savings | Less packaging, fewer cores, reduced labor | Extra core disposal, more frequent reloads |

Cost Effectiveness | More labels per stack, fewer changeovers | Varies; smaller rolls increase handling time |

Less Waste | No cardboard core to discard | Cardboard core and excess liner waste |

More Waste | Minimal; only the backing liner | Core and liner must be thrown away |

More Individual Labels | 1,000–2,000 per stack typical | 250–1,000 per roll typical |

Reloading Time | Longer intervals between reloads | More frequent reloading |

Ideal Choice | High volume, industrial printers, shipping | Low to medium volume, small office printers |

Specific Needs | Suitable for long batch runs, fast output | Suitable for mixed jobs, short runs |

Store | Flat stacks; easy to store in boxes | Rolls; require racks or holders |

Advantages | Space-saving, less waste, fewer reloads | Flexible, wide range of label shapes/sizes |

Shop | Available from packaging suppliers in bulk | Widely available in various sizes and brands |

Ribbon | Supports both direct thermal and ribbon (thermal transfer) printing | Supports both direct thermal and ribbon printing |

Point | Efficient for large orders and fast operations | Best for smaller jobs, quick swaps, or mixed labels |

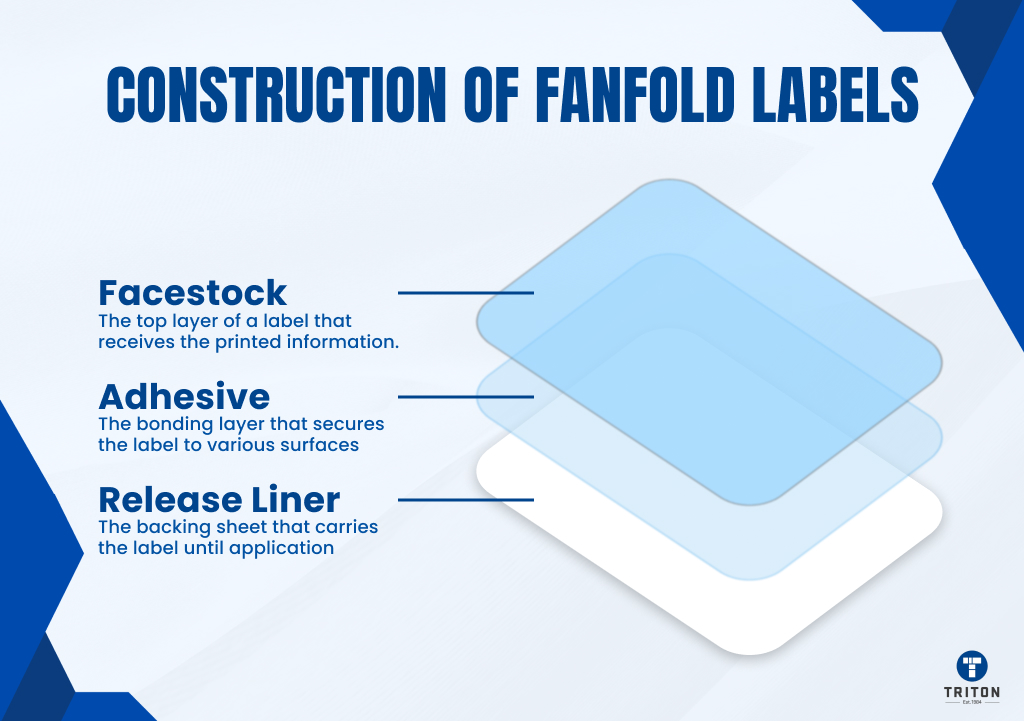

A typical fanfold label has three distinct layers. These materials are chosen to support the thermal printing process and effective final application. The core components are.

Some labels have an added topcoat on the facestock for enhanced printability, moisture, or chemical resistance, especially for synthetic facestocks or colour inkjet applications.

Between each label, perforations or die-cuts allow for easy separation and smooth feeding through thermal or industrial printers.

Liner material impacts the speed and cleanliness of the printing process, as well as recyclability.

Component | Common Materials | Purpose / Selection Notes |

|---|---|---|

Facestock | Direct thermal paper, thermal transfer paper, BOPP, PET, PE | Printing surface; determines print method and durability |

Adhesive | Permanent, removable, freezer, specialty | Bonds label to application surface |

Release Liner | Silicone-coated paper, film (PET, PP) | Carries and releases labels; affects speed/compatibility |

Topcoat (opt.) | Protective varnish, synthetic coating | Increases durability, moisture/chemical resistance |

Perforations | Mechanical cuts or die-cuts | Enables easy separation and smooth printer feeding |

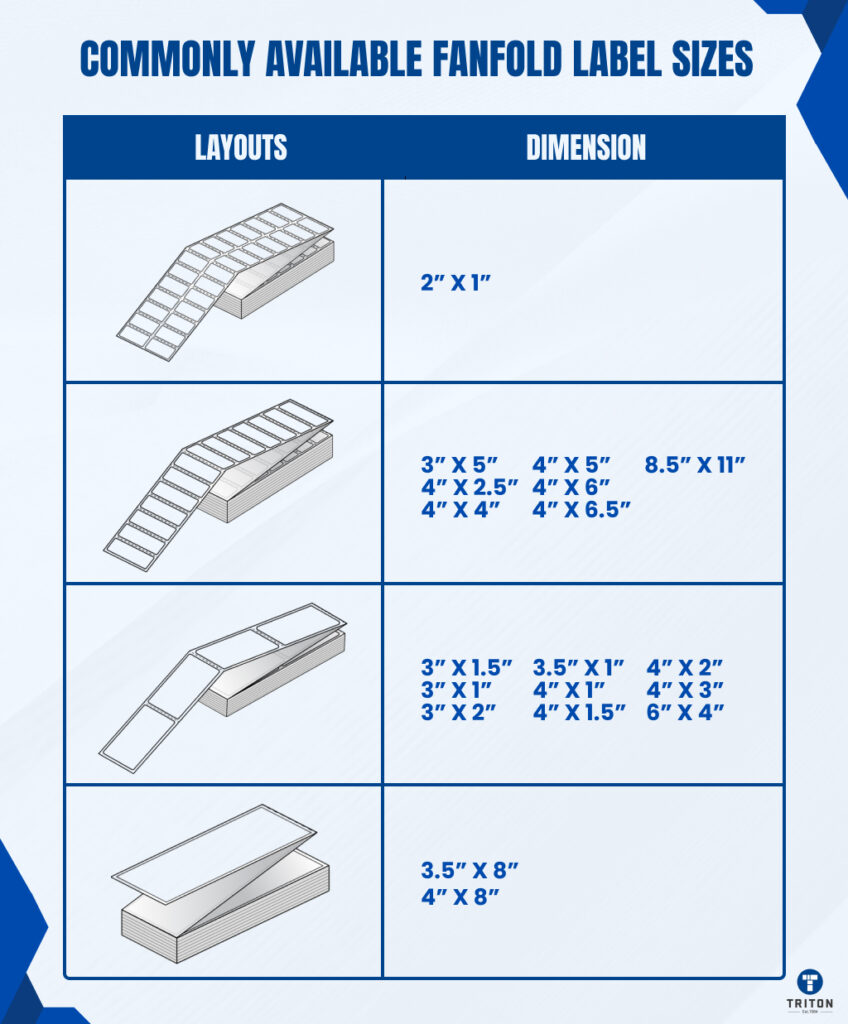

Fanfold labels are manufactured in a variety of standard sizes to align with shipping, inventory, and compliance workflows. The 4″ x 6″ label is the default for carriers, including UPS, FedEx, DHL, and USPS. Smaller formats, such as 2″ x 1″ and 3″ x 1″, enable high-volume barcode and product labelling, with stacks exceeding 20,000 labels to minimise reloading during batch printing.

Larger sizes, such as 4″ x 8″, 6″ x 4″, and 8.5″ x 11″, are used for applications that require more print space, such as regulatory documentation, detailed packing lists, or pallet identification. Stack counts decrease as label size increases – a trade-off between label dimensions and quantity per box.

The following table summarises the most widely used sizes, typical stack counts, and their primary business applications, supporting informed label selection for specific operational requirements.

Size (Width x Height) | Typical Labels per Stack | Common Applications | Format Notes |

|---|---|---|---|

2″ x 1″ | 20,900-25,000 | Small product labels, barcode labels | Available 2-across format |

3″ x 1″ | 10,450-12,500 | Inventory tracking, small shipping labels | Single label format |

3″ x 2″ | 5,580 | Product labeling, inventory management | Perforated design |

3″ x 5″ | 2,300 | Medium shipping labels, product information | Single label format |

4″ x 2″ | 6,000 | Shipping labels, warehouse labeling | Single stack format |

4″ x 2¼” | 4,000 | Industrial labeling, product identification | Thermal transfer format |

4″ x 3″ | 4,000 | Mailing and shipping applications | Standard white direct thermal |

4″ x 4″ | 3,000 | Square labels for products, packaging | Direct thermal format |

4″ x 6″ | 500-2,000 | Standard shipping labels, e-commerce | Most popular shipping size

|

4″ x 6½” | 2,000 | Extended shipping labels, detailed information | Thermal transfer format |

4″ x 8″ | 1,000-1,250 | Large shipping labels, detailed packaging | Premium top-coated available |

100mm x 150mm (≈4″ x 6″) | 4,000 | International shipping, logistics | Metric sizing standard |

102mm x 150mm (≈4″ x 6″) | 4,000 | International applications | Direct thermal format |

103mm x 150mm (≈4″ x 6″) | 500 | E-commerce shipping, warehouse use | Compact stack size |

5″ x 4″ | 2,500 | Large product labels, industrial use | Thermal transfer format |

6″ x 4″ | 2,500 | Wide format labels, detailed information | Large format applications |

8.5″ x 11″ | 1,000 | Full page labels, documents | Letter-size format |

Fanfold labels are ideal for high-volume, continuous printing. They are easy to align and are simple to handle. Their flat-stacked design requires less storage space. Available in a variety of facestock, these labels are widely used across logistics, retail, and manufacturing.If you are looking for a thermal printer for your labelling needs, Triton Store offers a full range of thermal label printers from trusted brands like Zebra, TSC, and SATO, with models that support fanfold, roll, and speciality label media. Visit the Triton Store now. We also offer fanfold thermal transfer labels in blue, purple, red, yellow, and white colours. Each label measures 102 x 150 mm and comes in 3,000 per box, available exclusively on our Australian store.