Industrial PCs were a $5.9 billion market in 2024, and are projected to reach $8.85 billion by 2031.

Industry 4.0 initiatives are driving much of this demand. Companies implementing smart manufacturing report 20-40% productivity gains from industrial PC deployments. The convergence of operational technology with technologies like IIoT, digital twins, and edge AI requires reliable computing platforms.

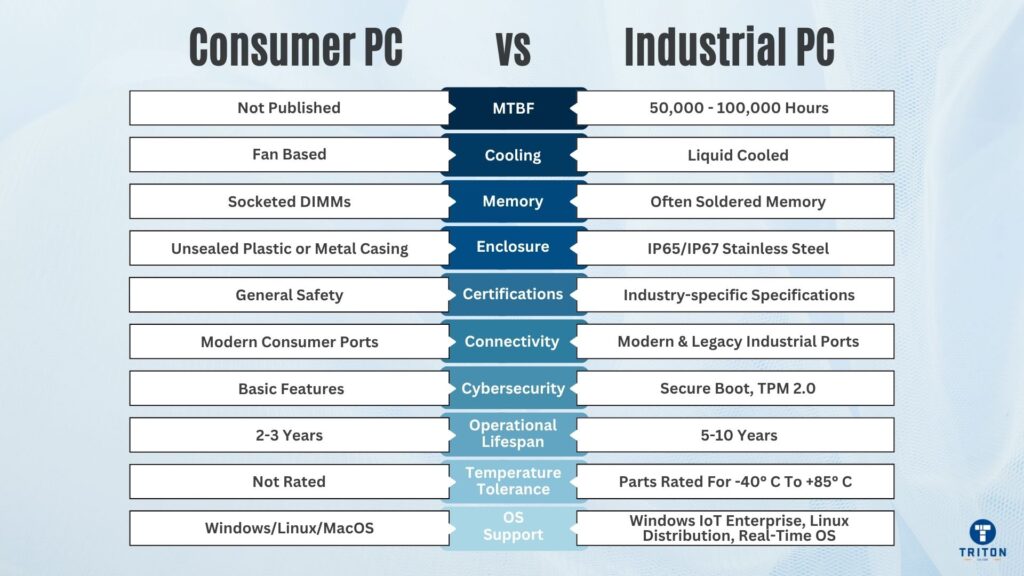

While consumer PCs prioritise performance and low cost, industrial PCs prioritise reliability and longevity in harsh environments.

The difference matters.

A consumer PC operating on a factory floor will typically fail within months due to dust, vibration, and temperature extremes while an industrial PC will operate continuously for years. This reliability translates directly to business value as manufacturing downtime costs $10,000 to $100,000 per hour.

An industrial PC is a computer engineered for industrial environments. While consumer PCs optimise for peak performance and low cost, industrial PCs optimise for continuous operation in harsh conditions.

Component selection drives this reliability.

Industrial PCs use parts rated for -40°C to +85°C temperature ranges. Some industrial PCs use fanless cooling through chassis heat dissipation, which eliminates mechanical failure points.

Many embedded and fanless industrial PCs use soldered memory that can withstand vibration and shock, though larger rackmount systems do use socketed DIMMs for servicing ease.

The reliability of IPCs is quantified by Mean Time Between Failures (MTBF) ratings.

Industrial PCs are rated at 50,000-100,000+ hours MTBF under standards like MIL-HDBK-217F or Telcordia SR-332, while consumer systems generally lack published MTBF data and use components with shorter service expectations.

Industrial PCs have 5-10 years operational lifespans versus 2-3 years for consumer hardware.

Fanless industrial PCs with aluminium fin arrays and heat pipes support processors in the 35-65 W TDP range. Higher-power CPUs generally require active cooling.

Some advanced industrial PC designs use vapour chamber technology to improve heat transfer, though exact thermal resistance values are rarely published in vendor specifications.

Industrial PCs run components below their maximum rated load – a practice known as derating – to reduce stress and extend lifespan during 24/7 operation.

Metal dust, vibration, chemicals, and temperature extremes damage computer electronics within weeks.

Industrial PCs solve this with sealed IP65 rated enclosures, fanless cooling, and components rated for continuous operation at -20°C to +70°C.

These systems connect directly to PLCs via industrial Ethernet protocols, whilst surviving paint booth chemicals and press shop impacts.

Energy facilities demand computing systems that comply with nuclear safety and explosive-atmosphere standards. Specialised industrial PCs are designed with options such as ATEX Zone 2 certification for hazardous locations and 10CFR50 Appendix B compliance for nuclear environments, along with wide-range power inputs that tolerate unstable supply conditions in remote sites.

Transportation requires vibration and shock resistant computers while ensuring uninterrupted, safety-critical operation. For example, railway applications require EN 50155 certification. This certification confirms that equipment can survive temperature cycles from -40 °C to +70 °C and vibration intense enough to destroy conventional hard drives. To achieve this, industrial PCs employ solid-state storage and rugged & shock absorbant chassis.

Healthcare facilities need computers that meet medical device safety standards without contaminating sterile environments. Consumer PCs with fans draw in particles and bacteria, while plastic cases cannot withstand chemical cleaning. Medical PCs are IEC 60601-1 certified. These are fanless have stainless steel enclosures that can be autoclave sterilised.

Outdoor infrastructure puts harsh demands on computing systems, from weather exposure to vandalism and unstable power supply. In smart city deployments, industrial PCs are protected by IP66 enclosures that keep out rain and dust, while wide temperature tolerance ensures reliable operation through summer heat and winter cold. To guard against power spikes, outdoor PoE surge protectors rated for up to 10 kV discharges reduce downtime and protect critical infrastructure. With corrosion-resistant stainless steel or powder-coated alloy enclosures, these systems remain dependable in coastal and industrial areas where salt, moisture, and pollutants would otherwise cause rapid deterioration.

Computers in process industries are sometimes exposed to ambient temperatures up to 70 °C, with nearby surfaces exceeding 200 °C. Some environments also contain explosive dusts such as flour or coal, which account for 50–60 reported dust explosions globally each year, and corrosive chemicals that can degrade unprotected enclosures within months. Industrial PCs for these environments are certified to SIL (Safety Integrity Level) standards under IEC 61508 for functional safety. Chemical-resistant (ISO 9227) allows these systems to withstand corrosion that would quickly destroy standard enclosures.

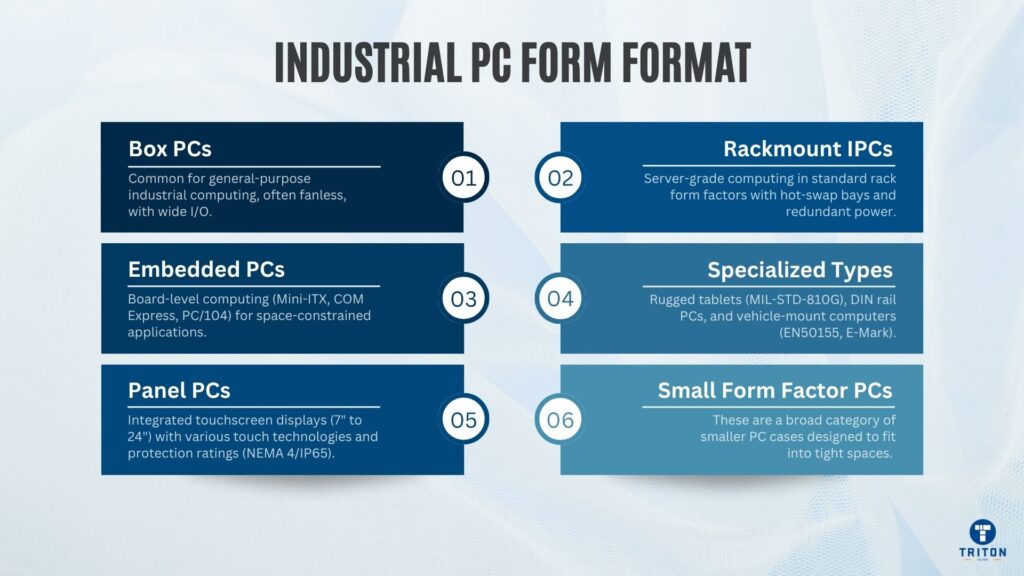

Box PCs are the most common in general-purpose industrial computing. Fanless variants typically use Intel processors, DDR4/DDR5 memory up to 64GB, and M.2 NVMe storage. These are rated for -20 °C to +70 °C, and have IP54/IP65 protection. These systems support multiple mounting options and have a wide choice of I/O, like USB 3.2, dual Gigabit Ethernet, and legacy serial ports.

Embedded PCs provide board-level computing in Mini-ITX, COM Express, and PC/104 form factors for space-constrained applications. COM Express modules have standardised pinouts with Intel Core/Atom processors and DDR4/DDR5 support up to 64GB. PC/104 systems deliver military-grade stackable computing at a 90mm x 96mm footprint with self-stacking architecture without backplanes.

Panel PCs have displays from 7″ to 24″ with projected capacitive or resistive touch. Some models have NEMA 4/IP65 front bezel protection for HMI applications. Processors range from Intel Atom to Core i7 with 4-32GB RAM, operating at -20°C to +60°C with 300-1000 nits brightness for sunlight readability. Some models have stainless steel 316L cases for food and pharmaceutical applications.

Rackmount IPCs provide server-grade computing in 1U/2U/4U form factors with hot-swap drive bays, redundant power supplies, and remote management via IPMI.

Industrial PCs are also sold in specialised types like rugged tablets with MIL-STD-810G certification and 4-8 foot drop specifications, DIN rail PCs for control cabinet mounting with 9-36VDC input, and vehicle-mount computers with EN50155 railway or E-Mark automotive certification featuring anti-vibration design and CAN bus interfaces.

1. Environmental Robustness

Not every site needs a fully ruggedised PC. In pharma labs, a standard IP20/IP40 chassis may suffice. But in a steel mill or sawmill, dust and debris destroy fan-cooled systems quickly. Always ask vendors for IP65/IP67 ingress ratings if your PCs will live near dust, oil mist, or washdown zones.

2. Temperature & Thermal Management

Freezer warehouses, outdoor kiosks, or furnace control rooms all need wide-range temperature tolerance (–20 °C to +70 °C or more). If your environment is controlled, you don’t need to over-pay for extended specs. Ask for temperature shock test reports and confirm whether cooling is passive (fanless) or active.

3. Shock & Vibration Durability

Industrial PCs installed inside control cabinets on stable shop floors face very less vibration. In contrast, systems mounted on cranes, vehicles, or railcars endure constant vibration and mechanical stress. Buyers should verify IEC 60068-2-64 or MIL-STD-810 compliance, and specify solid-state drives with shock-absorbing mounts for reliable operation in high-vibration environments.

4. Performance & Scalability

A simple HMI may run happily on an Atom processor, while machine vision or AI workloads demand Core i7/Xeon with GPU acceleration. Look for expandable RAM, PCIe slots, and M.2 storage to give you headroom for future upgrades without a forklift replacement.

5. Connectivity & Expansion

Legacy ports still matter. The food packaging industry still runs RS-232 connected weight scales. Check if the PC has both modern Ethernet/Wi-Fi and legacy serial/parallel I/O. Always map your existing PLCs, sensors, and SCADA networks before you finalise I/O requirements with the vendor.

6. Certifications & Compliance

Buying for a refinery? You’ll need ATEX or IECEx. Buying for the parma industry? Look for IEC 60601-1. An industrial PC without the right certifications delays deployment. Make certification checks part of your RFQ template, so you don’t get caught late in the procurement cycle.

1. Real-Time OS & Latency Guarantees

Use cases like motion control and robotics depend on predictable response times. Industrial PCs in response time sensitive use cases should support real-time operating systems like QNX or VxWorks, or deterministic networking such as Time-Sensitive Networking (TSN). Request latency benchmarks under real workloads to ensure sub-millisecond response where required.

2. Cybersecurity & Firmware Management

Unpatched firmware and software are sitting ducks for hackers, therefore look for features such as secure boot, and TPM 2.0 chips. Learn about your vendor’s security patch policy and timelines.

3. Lifecycle & Supply-Chain Planning

While most industrial PCsvendors guarantee 5-7 year support, policies differ. Confirm vendor commitments for EOL notifications and last-time-buy options.

4. Total Cost of Ownership (TCO)

Upfront hardware cost is 20-30% of TCO. Buyers must account for energy use, downtime risk, maintenance, and upgrades. A higher-quality IPC proves cheaper over 5 to 10 years because a longer service life reduces replacement and integration costs.

5. Customisation & Pilot Testing

Good vendors provide custom OS images, pre-loaded SCADA/HMI software, and burn-in testing. However, you should also insist on a pilot unit before large-scale deployment, as real-world testing could reveal EMC, heat, or protocol issues that paper specifications cannot.

Industrial PCs (IPCs) must comply with foundational safety standards to ensure protection against electrical hazards and system failures:

Deployment environments often impose sector-specific requirements beyond general safety:

Industrial PCs manufacturing and lifecycle must also align with environmental legislation:

IPCs must not interfere with and must withstand interference from other systems:

IPCs deployed in railroad systems require certification for rugged performance and EMC resilience:

In aviation IPCs must pass comprehensive environmental testing:

Marine-grade IPCs must be resilient to maritime conditions:

Industrial PCs vary widely in price depending on performance and form factor.

Entry-level embedded systems based on Intel Atom or Celeron processors are typically priced in hundreds of dollars. More powerful models with Core i5/i7 or Xeon processors generally start above $1,500 and can cost several thousand dollars when configured with high-performance options.

Operating systems are usually licensed separately, adding a few hundred dollars per unit. SCADA, HMI, and automation software are more significant cost drivers: licences can range from low to tens of thousands, depending on scale, modules, and vendor. Integration services (system setup, application deployment, and testing) are typically project-specific and often add several thousand dollars for a mid-sized deployment.

Training expenses depend on the user’s role. Operator-level training is generally limited to short sessions and modest cost, while advanced technician or engineering training for IPC maintenance, networking, or SCADA integration can be more substantial. Exact figures vary by provider and scope, but organisations should budget accordingly for both groups.

Energy consumption for fanless and embedded IPCs ranges from 15-150, which translates to a modest operating cost per system, though total site energy can be material in larger fleets.

Maintenance and support contracts are priced at a percentage of hardware value, around 10-15% annually. Users should also budget spare units and parts, as these provide insurance against lead times and product obsolescence.

Downtime is the critical operational risk. Average downtime in general manufacturing costs $300,000 or more per hour, while automotive and process industries have reported losses well above $1 million per hour.

This underscores the value of investing in higher-reliability hardware and proactive maintenance which is recouped even if one outage is avoided.

Planning for mid-life refreshes is good practice when operating systems reach end-of-life or when new performance demands arise. Vendors typically offer long-term availability programs (5+ years of guaranteed component supply) to simplify lifecycle management, but buyers should still include obsolescence planning and certified disposal in TCO calculations.

Studies show the five-year TCO for industrial PCs in manufacturing runs between $3,500 and $6,000 per system, once hardware, software, and support are included. Well-planned automation projects deliver 15–30% annual ROI, with most buyers recovering costs in 2–4 years through higher uptime, lower labour needs, and productivity gains.

Industrial PCs are built for reliability in harsh conditions-dust, vibration, temperature extremes-where a consumer PC would fail quickly. They use rugged enclosures, fanless cooling, extended temperature-rated components, and long lifecycle support.

Most industrial PCs are designed for 5-10 years of continuous operation, with vendors offering long-term component availability programs. Consumer PCs typically need replacement every 2-3 years in the same environments.

You can, but it usually fails within months due to dust, shock, or heat. The downtime costs-often hundreds of thousands of dollars per hour in manufacturing-far outweigh the savings on cheaper hardware.

Prices start in the low hundreds of dollars for entry-level Atom or Celeron systems. High-performance Core i7 or Xeon models generally cost $1,500 and up. Total cost depends on performance, certifications, and software licensing.

They are used in manufacturing, energy, transport, healthcare, marine, aerospace, and smart infrastructure. Each sector often requires additional certifications like IEC 60601-1 (medical), EN 50155 (rail), or IEC 60945 (marine).

Common options include Windows IoT Enterprise, Linux distributions (Ubuntu, Red Hat, Yocto), and real-time operating systems such as QNX or VxWorks. Choice depends on application requirements and software ecosystem.

Fanless IPCs use heat sinks and conduction cooling instead of fans. This prevents dust ingress, eliminates moving parts, and improves reliability in environments where fans would clog or fail.

They support industrial protocols like PROFINET, EtherCAT, EtherNet/IP, CAN bus, and OPC UA. Many models include legacy ports (RS-232/RS-485) alongside modern interfaces (USB 3.2, 5G, Wi-Fi 6).

Global leaders include Advantech, Siemens, Beckhoff, Kontron, OnLogic, AAEON, Nexcom, and B&R. Buyers should evaluate vendors based on certification coverage, lifecycle guarantees, and local support.

Key trends include AI and machine learning at the edge, 5G and Time-Sensitive Networking (TSN) for real-time data, virtualisation/soft PLCs, cybersecurity hardening (IEC 62443), and sustainability-driven designs.

Industrial PCs keep factories running, trains moving, and labs compliant. They’re built to last where ordinary computers fail.

Find hardware built for your environment at the Triton Store.