Dust and water often affect equipment in industrial environments. They can damage electronics, stop machines, or lead to safety problems. Ingress Protection (IP) codes help address these risks.

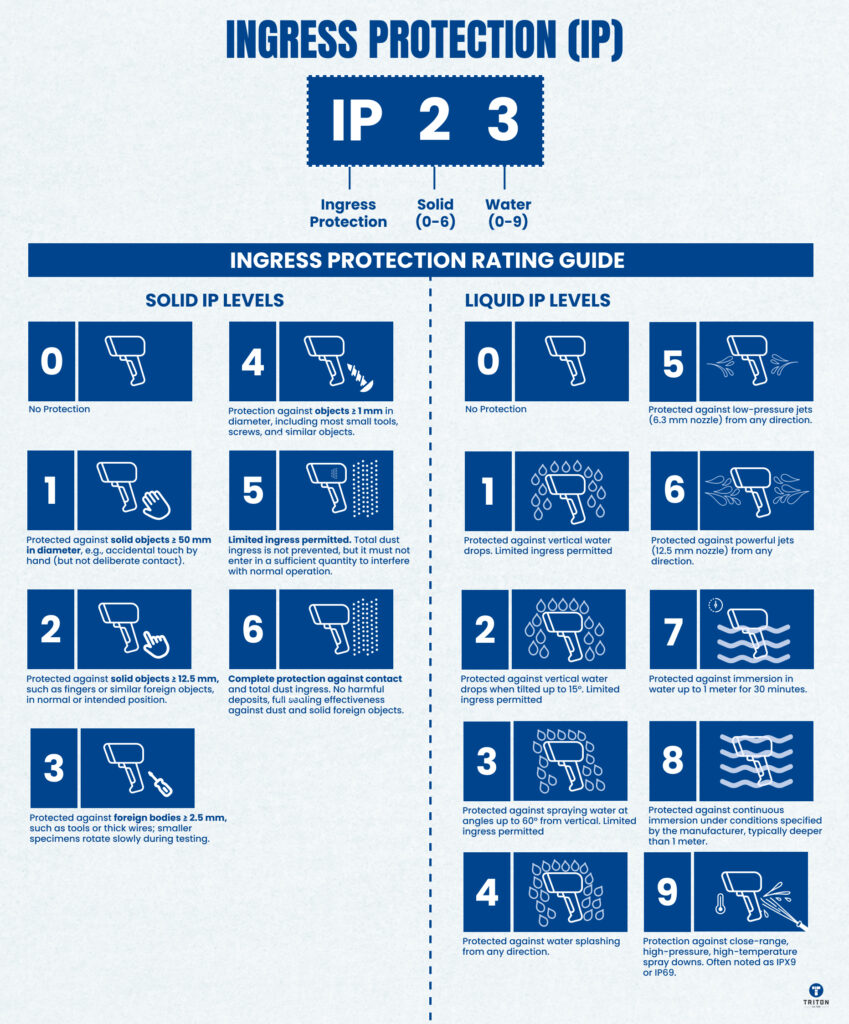

An IP code shows how well a device’s casing blocks solids such as dust and liquids such as water. Set by the IEC 60529 standard, each code starts with “IP” followed by two digits. The first digit shows protection against solids. The second shows resistance to liquids.

These codes are used in sectors like packaging, labelling, logistics, and automation. They help buyers choose equipment that suits the worksite-indoors, outdoors, or in cold storage. Terms like “waterproof” are unclear. IP ratings give clear, tested levels. For example, IP67 means full dust protection and short-term submersion. IP54 allows splashes but not immersion.

Using the correct IP code lowers the risk of faults caused by dust or water. It helps prevent downtime and supports workplace safety. This guide explains how IP codes work and why they are important when selecting equipment.

An IP code uses the format “IP” followed by two digits. Each digit shows how well a product’s enclosure blocks solid particles and liquids. The values are based on test methods set out in the IEC 60529 standard.

For example, IP65 means the device is completely protected against dust and can resist low-pressure water jets from any direction.

The first digit ranges from 0 to 6. It shows how well the enclosure stops the entry of solid objects, such as fingers, tools, or dust. A rating of 0 means there is no protection. Ratings from 1 to 4 refer to protection against objects of a certain size, from 50 millimetres down to 1 millimetre. Level 5 means limited dust may enter, but not enough to affect how the equipment works. Level 6 is the highest rating and means the enclosure is completely dust-tight.

The second digit ranges from 0 to 9. It shows how well the enclosure protects against water. A rating of 0 means no protection. Levels 1 to 4 include protection from dripping water or splashes. Levels 5 to 6 indicate protection against water jets. Level 7 means the enclosure can handle short-term submersion. Level 8 covers long-term submersion under pressure. Level 9, sometimes written as IPX9 or IP69, means protection against high-pressure, high-temperature water sprays used in washdown areas.

If one of the digits is not tested, it is replaced with the letter “X.” For example, IPX7 means the product has been tested for water protection but not for solids. Some codes may also include extra letters like “M” or “K” to show extra features, such as resistance to moving parts or high-pressure cleaning.

Each rating is based on specific testing, and knowing what each digit means helps buyers select the right equipment for their worksite. In the next sections, we will explain the test levels in detail and provide real-world examples from industrial settings.

The first digit in an IP rating shows how well an enclosure stops solid objects from entering. These objects include tools, wires, fingers, dust, and airborne particles. The scale runs from 0 to 6, with each level tested under IEC 60529 procedures. The higher the number, the better the protection.

The enclosure is completely open. It allows contact with internal parts and does not block any solids. Dust, insects, and even large objects like screwdrivers or cables can enter freely. Example: an open circuit board used in a test bench or inside sealed cabinets.

This level prevents full body contact with large objects such as the back of a hand, but offers no protection against tools or fingers. It avoids accidental contact but not much else. Example: basic fan covers that prevent hand access to moving blades but allow dust and small objects through.

Blocks entry by fingers or long items like thick pens, screwdrivers, or cables with similar diameters. Example: basic indoor switch housings that protect from casual finger contact but are not sealed from dust or small tools.

Prevents access by medium-sized tools such as pliers, thick wires, and nails. This rating is suitable for older machine housings or basic electrical boxes with limited exposure to fine debris.

Blocks thin tools, metal shavings, wires, screws, and insects. Commonly used in control panels, indoor switchboards, or general-purpose housings installed in light-duty environments.

The enclosure offers partial protection against dust. Fine particles may enter but not in enough quantity to affect function or safety. The enclosure is tested inside a dust-filled chamber for several hours. Example applications include label printers, photoelectric sensors, wireless access points, and mobile computers used in logistics, light manufacturing, or packaging.

Offers complete protection against dust and fine particles. The enclosure must pass a vacuum test inside a chamber with suspended dust. No particles are allowed to enter. This level is used in environments with airborne powder, sawdust, flour, or mineral dust. For example, Zebra’s 3600 series and the Honeywell Granit 1990iSR scanner are dust-tight and used in dusty warehouses.

The second digit in an IP rating shows how well an enclosure prevents water from entering. It covers a range of risks, from light rain to high-pressure hose cleaning. These ratings are defined under IEC 60529 and tested using controlled water exposure. The scale runs from 0 to 9.

The enclosure offers no defence. Even a few drops of water may enter and damage internal components. Example: open-frame PCBs or devices designed only for sealed environments.

Blocks dripping water falling straight down for 10 minutes. It simulates condensation or light rain. Example: a device installed under a solid roof but still exposed to moisture. Rare in industrial use.

Similar to Level 1, but tested while the enclosure is tilted at an angle. It simulates water falling onto sloped surfaces. Example: control switches or displays mounted at an angle under shelter.

Resists light spraying at angles up to 60 degrees from vertical. Example: outdoor terminals, intercoms, or sensor housings mounted under an awning or canopy.

The enclosure withstands splashes from every side. It is tested using an oscillating spray for 10 minutes. Suitable for forklift-mounted devices, workstations near sinks, or panels near washdown areas.

Resists water jets from any direction, including routine hose-down cleaning. Water flow is around 12.5 litres per minute from 2.5 to 3 metres away. Example applications: floor label applicators, mobile label printers, outdoor camera housings, and panel enclosures near cleaning zones.

Withstands strong jets of water used in higher-pressure cleaning. Suitable for equipment exposed to large spray volumes or strong washdown routines. Common in outdoor controllers, agricultural machinery, and food packaging equipment.

Tested by submerging the enclosure in water up to 1 metre deep for 30 minutes. No water should enter in a way that affects use. Suitable for gear that may fall into puddles or operate in high-humidity zones. Example: handheld scanners used near wet floors or cold storage units where condensation forms.

The enclosure is sealed against long-term immersion. Test depth and time are defined by the manufacturer but usually exceed 1 metre for over 30 minutes. Suitable for submersible sensors, outdoor enclosures in flood-prone areas, and field-deployed wireless nodes.

Also marked as IPX9 or IP69. Resists steam jets and hot water cleaning at close range. Tests use pressurised water at around 80°C. Designed for use in meat processing, dairy plants, beverage factories, and pharmaceutical zones where hot washdowns are routine. Example: panel PCs in cleanrooms or sensors used near conveyors sprayed daily with hot water.

Some devices carry more than one rating to reflect different threats. A printer rated IP65/IP67 can resist both high-pressure spray and temporary immersion. This layered protection is useful in factories, food handling zones, and outdoor installations.

IP ratings are not just technical details. They are a practical tool for selecting equipment that will operate safely and reliably in harsh industrial environments. In places like warehouses, cold storage rooms, factory floors, and outdoor yards, equipment must handle daily exposure to dust, moisture, and other challenges. Choosing the right IP rating ensures the equipment stays functional, safe, and cost-effective over time.

Dust, dirt, and water are leading causes of equipment failure in industrial sites. A printer with a low IP rating placed in a logistics hub might fail due to airborne dust or spills. By contrast, an IP65-rated scanner can resist these elements and keep working during daily operations. Higher IP ratings help reduce downtime caused by moisture or dirt entering the device. As a result, production lines run smoother, and businesses face fewer service interruptions.

IP-rated enclosures keep out harmful particles and moisture that can damage internal parts. For example, a dust-tight motor (IP6X) avoids build-up that would otherwise lead to wear or overheating. A sealed panel (IPX5 or higher) avoids rusted contacts and short circuits. By protecting internal systems from corrosion and mechanical wear, IP-rated gear lasts longer and needs fewer repairs. This protects capital investments and lowers replacement costs.

A failure caused by water inside an electrical panel can cause electric shocks or short circuits. In some industries, such as grain processing or mining, dust entering electrical parts can lead to fire or explosions. Proper IP ratings help reduce these risks. An IP6X enclosure, for instance, keeps combustible dust away from hot surfaces or exposed circuits. An IPX4 or higher panel stops dripping water from creating hazards. These protections reduce the risk of injury and keep the work environment safe.

Many sectors require equipment to meet certain IP ratings. In food production, for example, gear must often meet IP69K to allow for hot water washdowns. Outdoor electrical boxes must meet legal standards, such as IP55 or higher, to comply with safety codes. In explosive zones, IP-rated gear is often paired with ATEX or IECEx certification. Manufacturers like Honeywell and Zebra include IP ratings on product labels to show they meet these strict requirements. Using the correct rating helps businesses pass inspections and stay compliant.

The right IP rating depends on how and where the device will be used. A warehouse with airborne fibres, concrete dust, and occasional water spray may need IP65 devices. A bottling plant with constant humidity and washdown procedures might require IP67. In cold storage, where condensation can build up during temperature shifts, sealed enclosures prevent moisture from reaching the electronics. IP ratings also often align with strong physical construction, offering better protection against impact and cold.

Failure caused by water or dust is one of the main reasons for unplanned maintenance. While failure rates vary by site, companies that select equipment with proper IP ratings report lower repair costs and fewer disruptions. IP codes offer a measurable level of protection, helping engineers select the right tool for the job. Choosing a low rating in a harsh setting often leads to early failures. Choosing the correct or higher rating leads to long-term savings and peace of mind.

Not every industrial device needs the highest level of ingress protection. However, three ratings appear frequently in industrial applications because they balance cost, protection, and usability: IP54, IP65, and IP67. Below is a breakdown of what each rating means and where it is typically used.

An IP54 rating means the device is protected against limited dust ingress and splashes of water from any direction. Dust may enter, but not enough to affect performance. The device can also withstand light water exposure, such as drips or splashes.

Applications

IP54 is common in warehouse and logistics settings where the equipment may encounter cardboard dust, condensation, or occasional splashing. These devices are not suitable for pressure washing or heavy dust, but they handle everyday indoor challenges well.

Product Examples

This rating provides basic durability. It prevents immediate failure from light contact with dust or liquid, but is not meant for use in wet or highly dusty areas.

IP65 indicates full protection against dust and resistance to low-pressure water jets from any angle. It is one of the most common ratings for indoor and outdoor industrial use.

Applications

IP65-rated devices are used on factory floors, in outdoor yards, and in production zones where equipment may be sprayed with water or exposed to airborne particles. This level is also used for enclosures cleaned with a hose.

Product Examples

IP65 is a minimum standard for environments where water jets or direct spray are part of cleaning routines. It also serves well in outdoor sites.

An IP67 rating gives complete protection against dust and short-term immersion in water up to 1 metre for 30 minutes. This is considered a high standard for rugged and outdoor equipment.

Applications

This level covers all protection offered by IP65, plus resistance to submersion. It suits applications where devices may be dropped in puddles, used in rain, or exposed to frequent washdowns.

Product Examples

IP67 is preferred when durability and uptime are critical. It provides a strong barrier against environmental damage and often aligns with extended product life in rough settings.

Choosing the correct IP rating is an important part of selecting equipment for industrial use. The rating you choose affects not just performance, but also safety, compliance, and long-term costs. Both under-specifying and over-specifying the IP code can lead to problems, so the goal is to match the rating to actual conditions.

Start by looking at the area where the device will be used. Is it dry or humid? Is dust present? Could water come from rain, splashes, or cleaning? If the site is dusty—such as a grain mill or woodworking area—a first digit of 5 or 6 is necessary. If water exposure is likely, choose based on the level:

For example, a device in a food processing line should be rated IP66 or above, while a device used in a dry control room might only need IP20 or IP54.

Some equipment is installed in areas that stay dry during normal use, but cleaning may introduce water. If staff use a hose or pressure washer to clean machines, the devices must withstand that exposure. Even a once-a-week wash can damage an unsealed device.

If a product is regularly cleaned with low-pressure spray, IP65 may be enough. For high-pressure or hot water cleaning, such as in food or pharmaceutical facilities, IP69K is a better fit. The cleaning method is just as important as the daily environment when selecting an IP level.

Think beyond daily use. Could a device be dropped in water? Could a pipe burst and spray equipment? Could unexpected dust reach the device during a spill or production event? If the answer is yes, choose a rating that protects against these scenarios.

For example, a handheld scanner used outdoors may face dust, rain, and the risk of being dropped in water. In that case, IP67 is a better choice than IP54, even if most days are dry.

Some industries require a minimum IP rating by law or regulation.

Check the relevant standards for your industry. Sometimes they do not state the IP code directly, but the conditions described will align with a specific IP rating.

Higher IP ratings often mean added cost, larger size, or reduced airflow. Fully sealed devices may run hotter or be heavier due to extra sealing. For example, IP68 may cost more than IP67 but offer little benefit if continuous submersion is never expected.

Avoid choosing the highest rating by default. Instead, match the rating to the level of protection the site requires. However, also factor in the cost of failure. A device that fails due to moisture or dust can cause expensive delays, void warranties, or result in unsafe conditions.

IP ratings provide a clear and standard method for assessing how well equipment resists dust, water, and other environmental hazards. The right rating supports reliable performance, lowers maintenance costs, and helps meet safety and compliance requirements. Choosing too low a rating can lead to breakdowns. Choosing too high can increase costs without added value.

By understanding each rating and applying it to actual work conditions, buyers can choose equipment that lasts longer, performs better, and stays safe across industrial settings.