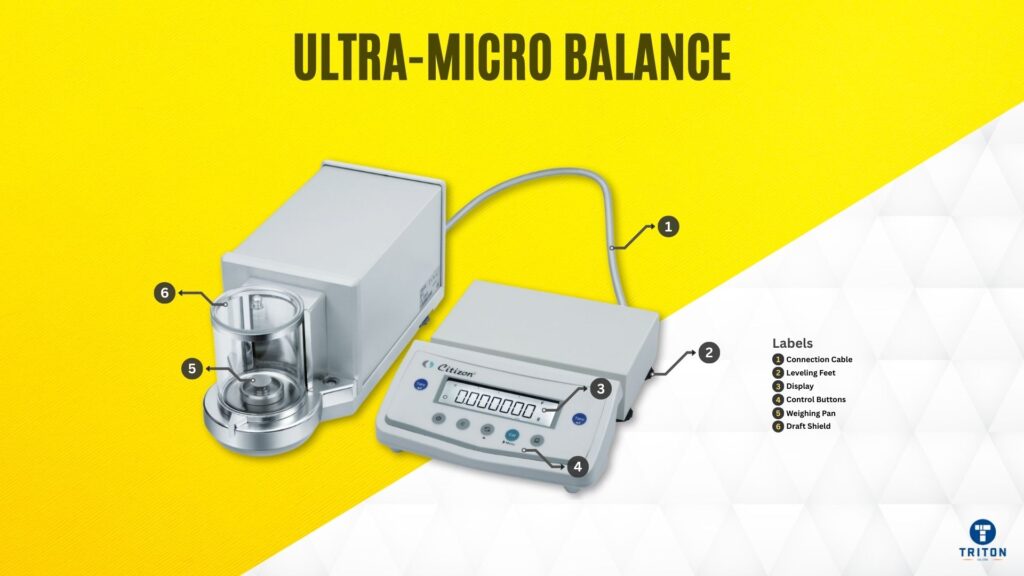

Analytical balances are precision measuring instruments that measure masses from about 200 g to sub-milligram levels, with readability ranging from 1 mg (0.001 g) to as fine as 0.1 microgram (0.0000001 g).

Buyers face three main variables: working principle, readability, and capacity.

Working principle determines how the instrument measures weight – most commonly, electromagnetic force restoration, strain-gauge, or resonant frequency.

Readability tells you the smallest increment the balance can display, from 1 mg for semi-analytical balances to 0.1 microgram for ultra-microbalances.

Capacity defines the maximum load, which usually decreases as precision increases.

In practice, selection is about matching the balance to the job. A food lab preparing formulations may only need 1 mg readability. A pharmaceutical QC lab will standardise on 0.1 mg. Environmental testing requires semi-micro or microbalances to detect trace amounts.

Each step up in precision adds cost and requires stricter environmental control – draft shields, anti-vibration tables, static management, and regular calibration.

This article explains analytical balances by working principle and readability/capacity, then links each type to everyday use cases. It also covers calibration and environment requirements, and addresses common buyer questions about drift, calibration, and total cost of ownership.

The goal is to provide a clear map of options so you can choose the balance that meets your precision needs without unnecessary spending.

Analytical balances can be grouped in several ways, each helping buyers decide which instrument fits their task:

The Lorentz Force is the underlying physical principle used in this balance.

The Lorentz force describes the force experienced by a current-carrying wire in a magnetic field.

A small pan is suspended in a magnetic field created by a coil. When a sample is placed on the pan, gravity pulls it downward. The system automatically increases the current in the coil to generate an electromagnetic force that pushes back up.

The balance monitors the exact current (directly proportional to the applied mass) required to hold the pan at its zero point. This closed-loop feedback design gives EMFR analytical balances high resolution.

The principle here is Hooke’s law, which relates strain in the material to the applied force.

A metal load cell element flexes slightly when weight is applied. Strain gauges bonded to the element change electrical resistance in proportion to the deformation. A Wheatstone bridge circuit converts this resistance change into a voltage signal, which is then scaled into a weight reading. Because the signal comes from physical strain, these balances are less sensitive than EMFR but very robust for higher capacities.

This type uses the principle of resonance physics, where added mass changes the natural frequency of an oscillating system.

A resonant balance contains a vibrating element, often a quartz tuning fork or silicon resonator, which oscillates at a fixed predefined frequency when no weight is added.

Adding mass to the element changes its natural resonance, lowering the vibration frequency. Sensors detect this frequency shift, and digital circuitry translates it into a weight value.

Because frequency can be measured with high precision, these balances deliver fast and stable readings with reduced sensitivity to temperature drift compared to other designs.

A quick reference for what buyers actually compare:

Before looking at calibration options and setup needs, it helps to understand why they matter. A balance can only deliver the accuracy on its datasheet if it is calibrated correctly and placed in a suitable environment.

For a first-time buyer, this is often overlooked.

Without proper calibration or a stable workspace, even the most precise balance will drift or give inconsistent results. This section explains how calibration keeps the balance accurate and how environmental factors like drafts, vibration, and static affect performance.

For many industries, the ability to weigh accurately is insufficient; documentation and compliance are just as critical.

Analytical balances often support GLP/GMP features such as automatic calibration and test results logging. Some models provide audit trails and user access controls to meet regulations like 21 CFR Part 11.

Connectivity options-USB, RS-232, or Ethernet-allow balances to connect with LIMS or printers for data transfer.

Buyers in regulated labs should also consider whether the balance comes with ISO or NATA calibration certificates and whether service providers can issue traceable reports.

Compliance requires alignment with the standards of NATA (National Association of Testing Authorities, Australia) or IANZ (International Accreditation New Zealand) in Australia and New Zealand, depending on the sector.

Including these features ensures that results are defensible in audits and that measurement records integrate smoothly into quality systems.

This depends entirely on your process tolerance. A precision balance with 1 mg (0.001 g) readability suits most general weighing tasks, such as preparing larger samples or quality control checks, where regulations are not extremely strict.

You must choose a 0.1 mg (0.0001 g) analytical balance when your work demands high precision. This is common in small sample size situations like research labs, pharmaceutical compounding, and environmental testing. If your quality system (like ISO or GMP) specifies a high degree of accuracy for weighing, an analytical balance is a must.

A drifting reading is the most common frustration. It signals that an external force is interfering with the highly sensitive weigh cell. The reasons are:

Internal checks are convenient but should be backed up with external checks on a schedule.

Precision mechanics, sensitive electronics, and environmental isolation drive costs; higher readability costs more.

You can, but you must manage the static they generate. Static is a significant source of error. To avoid issues, use an anti-static gun to treat the weigh boat immediately before placing it on the pan.

Alternatively, use glass or metal containers, as they do not hold a significant static charge. Special anti-static plastic weigh boats are also available and are a good option.

Heavy, rigid, and level. Consider an anti-vibration system for balances with 0.1 mg readability or finer.

Always match your application’s readability, capacity, minimum weight, calibration, and environment. With the right choice, you gain precision without over-investing.

Looking to equip your lab or production floor with the right balance? Visit the Triton Store for your measuring needs.